What is the wood grain aluminium profile process flow?

Update Time : 2023-Sep-20

Awesome ! Share To :

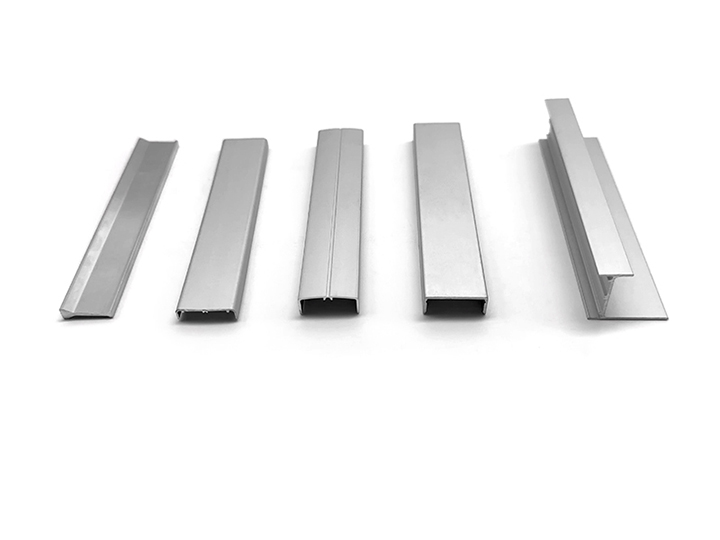

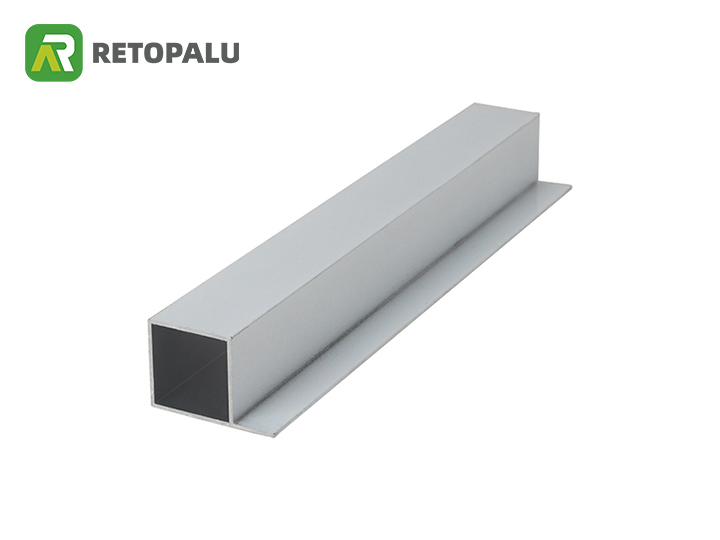

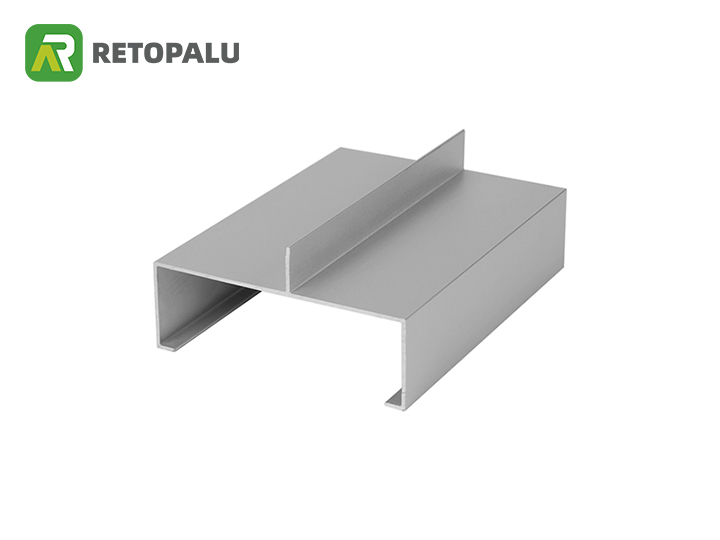

Wood grain aluminium profile is a fashionable metal decorative material. It is made of high-grade aluminum alloy sheets. According to the specific needs of the project site, it will go through a variety of technical processing steps such as cutting, bending, welding, grinding and polishing. The required size, shape and structure will then be formed.

Its surface will be covered with high-quality wood grain film, then vacuumed and finally formed. This material has been widely used in various interior decoration projects for ceiling and wall decoration, bringing unique decorative effects to indoor spaces.

Wood grain aluminum profile production process flow

- First, process it into the preset shape according to the drawing design. Next, pre-treatment by powder coating is required to remove oil stains and impurities on the surface of the aluminum finishes. Then carry out chromium treatment to enhance adhesion. Then spray.

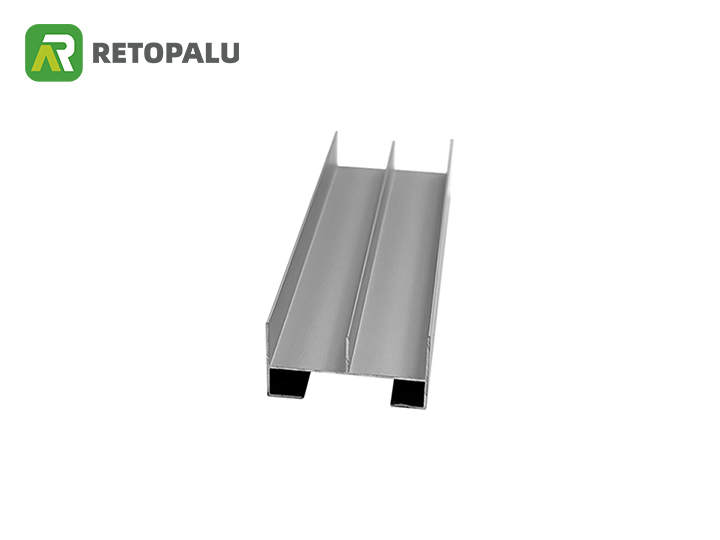

- Secnd powder coating: Powder spraying uses the principle of electrostatic spraying to adsorb the powder coating on the surface of the aluminum veneer. After heating at high temperature, the surface powder solidifies into a solid and bright coating.

- Wood grain transfer: Then wrap the sprayed aluminum sections with high-quality wood grain transfer paper, vacuum it, and fix it with high-temperature resistant tape to prevent the wood grain transfer paper from loosening and affecting the texture.

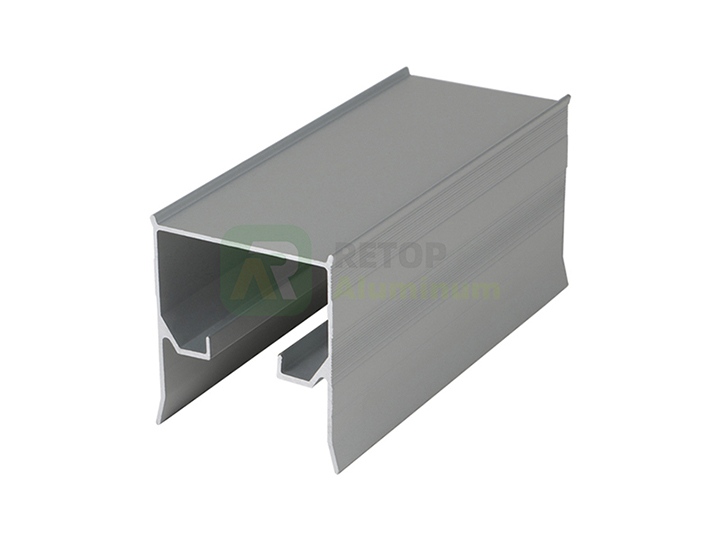

- Thermal transfer: The baking time and temperature need to be determined comprehensively based on the selected material and the depth of the transfer texture. Usually the transfer temperature is 160-180℃ and the time is 5-8 minutes.

- After heating is completed: Take out the wood grain aluminum profile, tear off the heat transfer paper and clean the surface.

Message