Comparison of powder coated and anodized aluminium profile

Powder coated and anodized aluminium profile is common aluminum profiles on the market. Spraying and anodizing are also common surface treatment methods for aluminum extrusions.

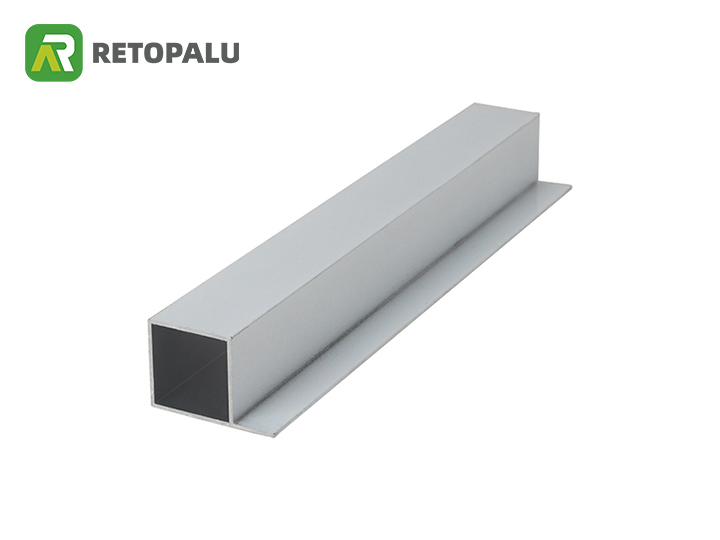

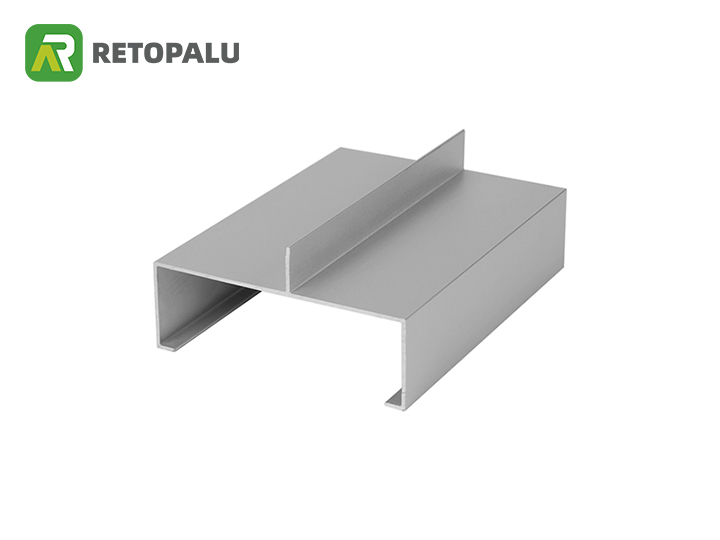

Anodized aluminum profiles

Aluminium profile’s anodizing process

Anodizing is to use the substrate as an anode and place it in the electrolyte for electrolysis to form a protective oxide film on the surface of the substrate.

Aluminum alloy profile anodizing process flow: base material → installation and hanging → degreasing → water washing → alkali etching → water washing → neutralization → water washing → anodizing → water washing → electrolytic coloring → water washing → hole sealing and water washing → drying → unloading → inspection → Packaging → warehousing.

Characteristics of anodized extrusion aluminium

- It has strong wear resistance, weather resistance and corrosion resistance.

- A variety of colors can be formed on the surface of the substrate to meet the color needs of different customers.

- It has strong hardness and is suitable for the production of various construction and industrial aluminum profiles.

Performance and film thickness of anodized aluminium profile

The thickness of anodized films from different manufacturers is different. The average film thickness of our Ruituo anodizing is 8-12um. We have 2 oxidation production lines, which can be up to 8 meters long.

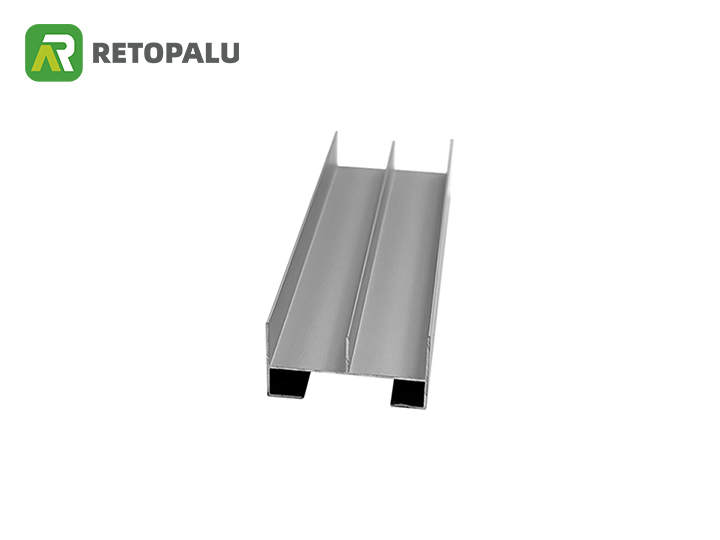

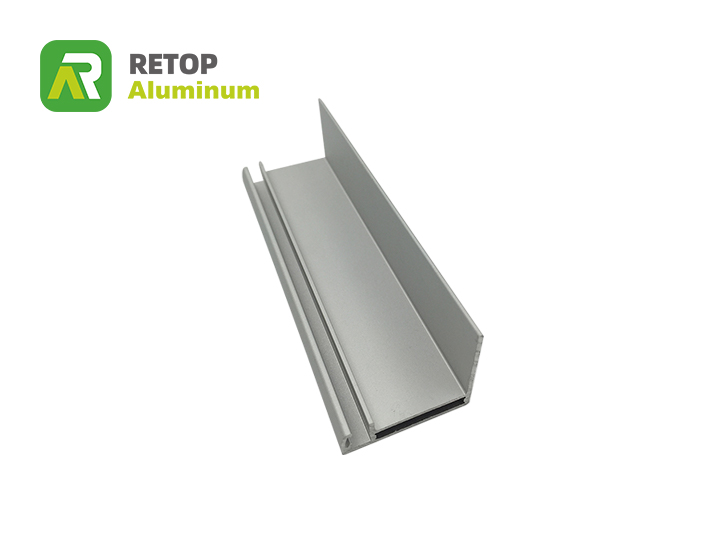

Powder coated aluminum profile

What is powder coating?

The process of powder coating aluminum profiles is a process including chroming, powder spraying, baking, etc. After powder coating, the paint film must be baked and solidified to form a hard and hard colored paint film on the original aluminum surface. It forms a kind of protection for aluminum materials, and its adhesion, uniformity, and weather resistance make the color of aluminum materials smoother and more uniform.

Basic principles of powder coating of aluminum alloy profiles

It is made of thermosetting saturated polyester powder, and after chromium treatment, the color is adhered to the product surface by spraying and dried at 200°C.

Aluminum profile powder coated process

Collecting materials and blowing aluminum chips → Inspection → Ticking → Water washing → Degreasing and degreasing → Water washing → Pure water washing → Chromization → Water washing → Soft pure water washing → Dripping → Drying → Inspection → Unloading → Inspection → Putting on shelves → Soot blowing → Spraying Powder→Inspection→Curing→Removal→Inspection→Packaging→warehousing.

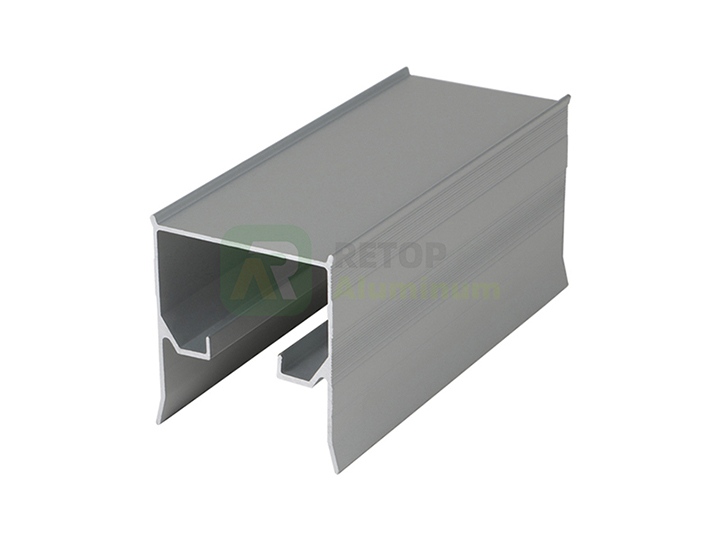

Which aluminum profile is less likely to fade, powder coating or anodized?

The powder coated and anodized aluminium profile generally do not fade. The reason why aluminum profile spraying and anodizing are not easy to fade is that they form a long-lasting protective layer on the aluminum surface. These protective layers can prevent color fading and surface wear. But in order to keep the color of aluminum profiles better, regular maintenance and upkeep is also very important.