Difference between aluminium section sliding and flat door

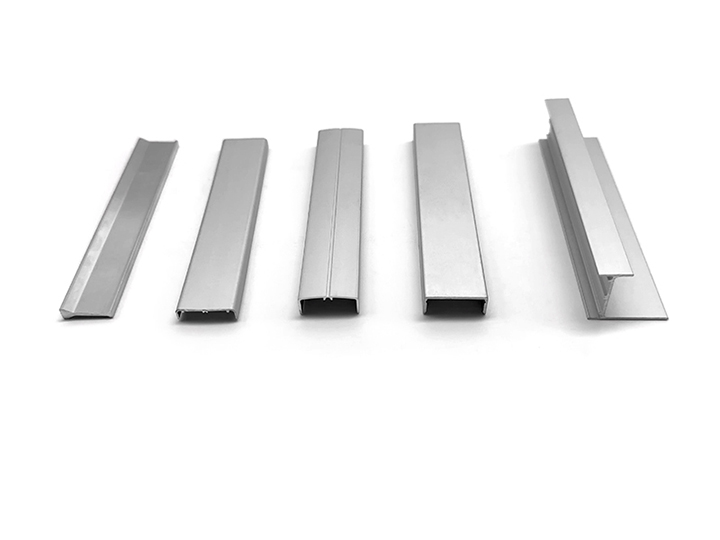

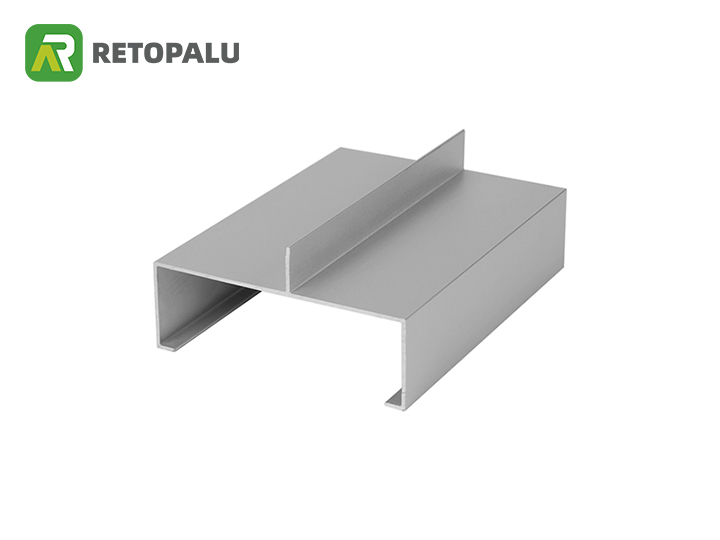

Aluminium section commonly used for aliminium profile sliding doors

Aluminium section for aluminium profile sliding doors are usually 6061 and 6063. These two alloys are strong, lightweight, and have good corrosion resistance. Their relatively low cost makes them ideal for sliding doors.

Aluminum 6061 is a heat-treatable alloy known for its superior strength, durability and corrosion resistance. It is also relatively easy to work with, making it widely used in a variety of applications, including sliding doors.

Aluminum 6063, on the other hand, is a non-heat treatable alloy known for its excellent formability, corrosion resistance and weldability. It is relatively inexpensive and is used for sliding door projects that do not require the extreme strength and durability of 6061 aluminum alloy.

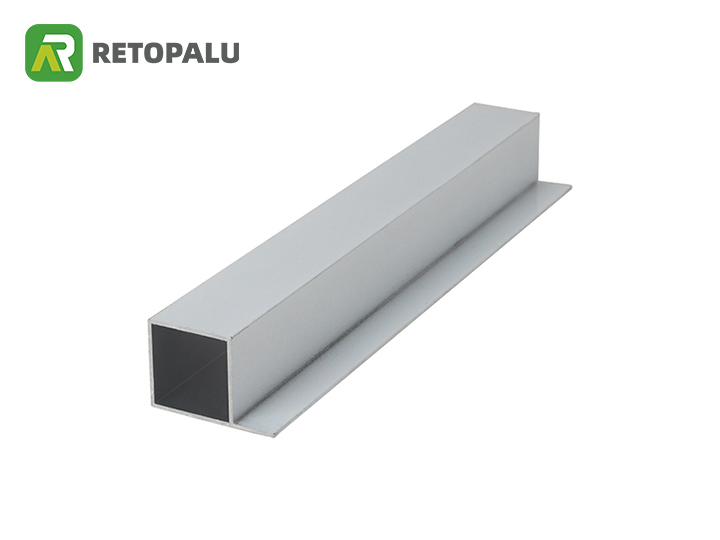

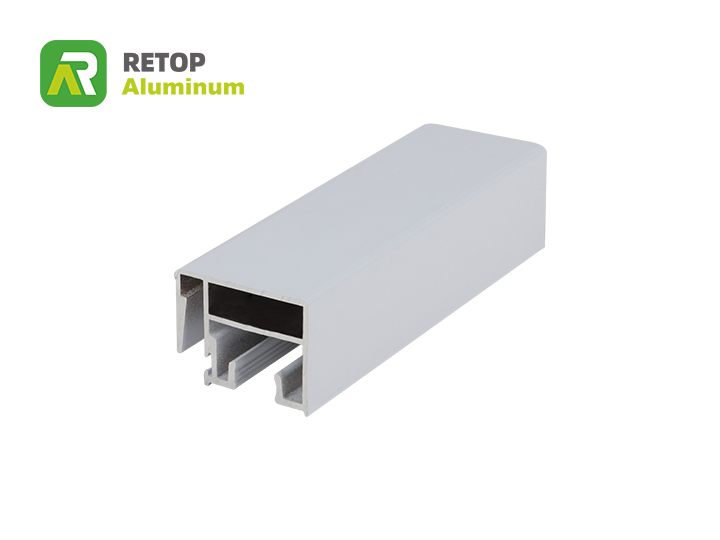

Aluminum extrusions usuallly used for casement doors

Aluminum sections commonly used for swinging doors, like sliding doors, are 6061 and 6063. however, swinging doors often require stronger aluminum alloys, especially if the door is larger or heavier.

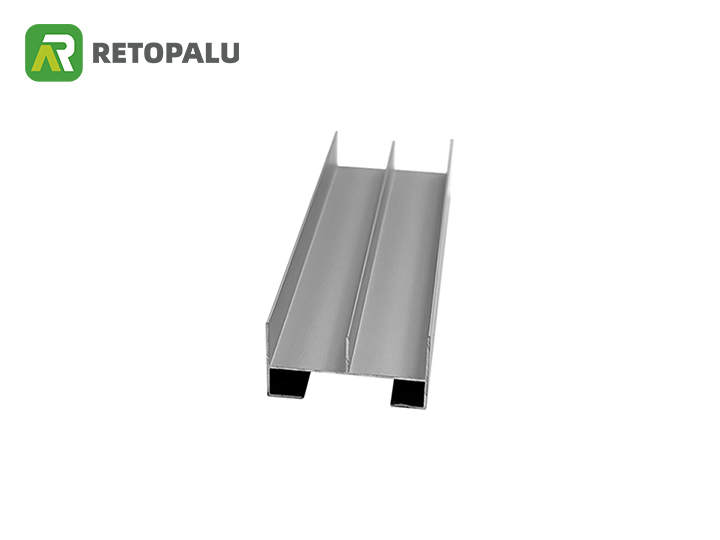

7075 aluminum profile is commonly used for swinging doors that need to withstand strong winds or other extreme weather conditions. 7075 aluminum alloy is known for its high strength, durability, and resistance to corrosion.

Other aluminum extrusions used for swinging doors include 6082 aluminum alloy and 5086 aluminum alloy. 6082 aluminum alloy has medium strength and is known for its good corrosion resistance and weldability. 5086 aluminum alloy is a non-heat treatable alloy and is known for its excellent formability and corrosion resistance.

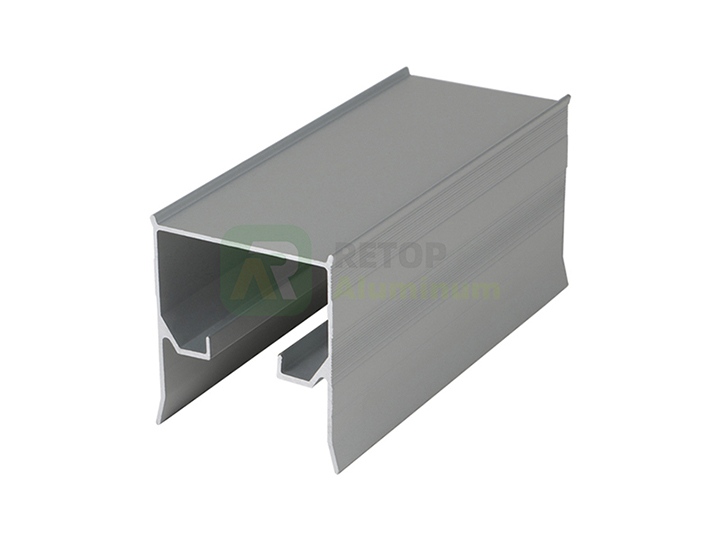

Factors to consider when choosing aluminum profiles for sliding or casement doors

1. Door size and weight: Larger, heavier doors require stronger aluminum alloys.

2. Door location: Doors exposed to extreme weather conditions, such as strong winds or snowy areas, require stronger aluminum alloys.

3. Intended use of the door: Frequently used doors such as front or back doors require more durable aluminum alloys.

4. PROJECT BUDGET: High-strength aluminum alloys are usually more expensive than low-strength aluminum alloys.