Anodized aluminum extrusions and their advantages

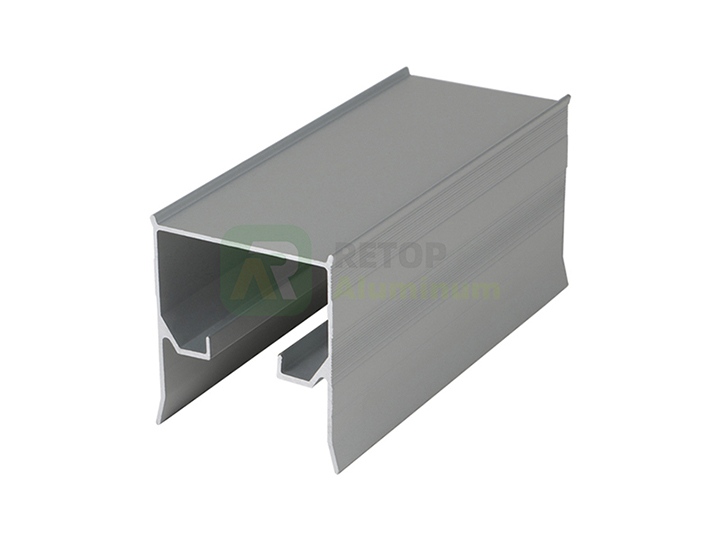

Anodized aluminum extrusions are aluminum alloys with an anodized surface. Anodizing is a chemical way of surface treatment. In recent years, aluminum profiles have risen in popularity in the market and have gained more and more popularity among consumers. This popularity is due to the fact that aluminum extrusions are cost competitive and excel in durability and customization. These qualities have made aluminum profiles the material of choice in people’s everyday products.

Among the aluminum sections, anodized aluminum profiles are preferred by more users. Anodized aluminum profiles can be used in more areas and have more advantages. So what is anodizing for aluminium profile and what are its advantages?

What is anodizing for aluminium profile?

Anodized aluminum extrusions are generally treated in an acidic solution to change their color and improve their durability. During the anodizing process, the aluminum oxidizes and forms an oxide film that makes it more resistant to corrosion. This layer is less than 100 microns thick, so it is not only very lightweight. Despite having a thin layer, it is very strong. On top of that, it has excellent scratch resistance compared to quartz. Anodised aluminium profiles can come in a variety of colors, so it is also decorative.

Wide application of anodised aluminium profiles

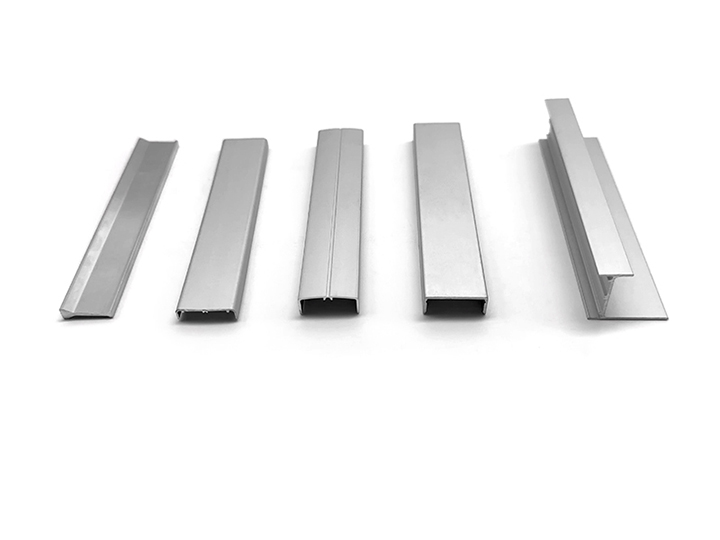

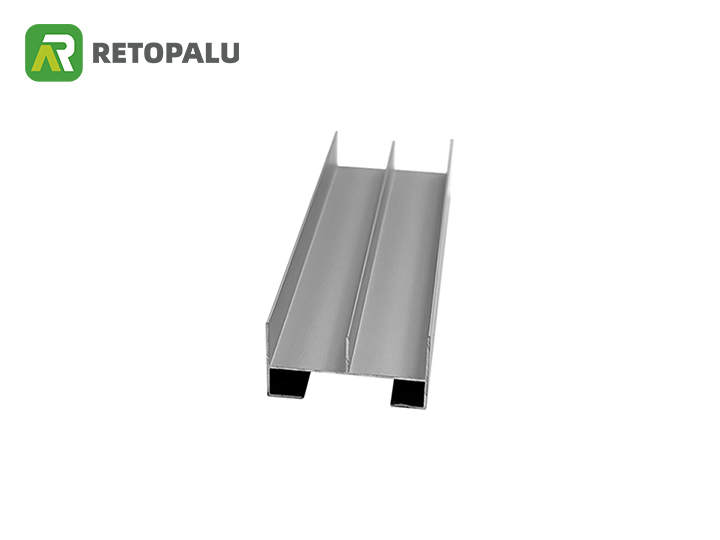

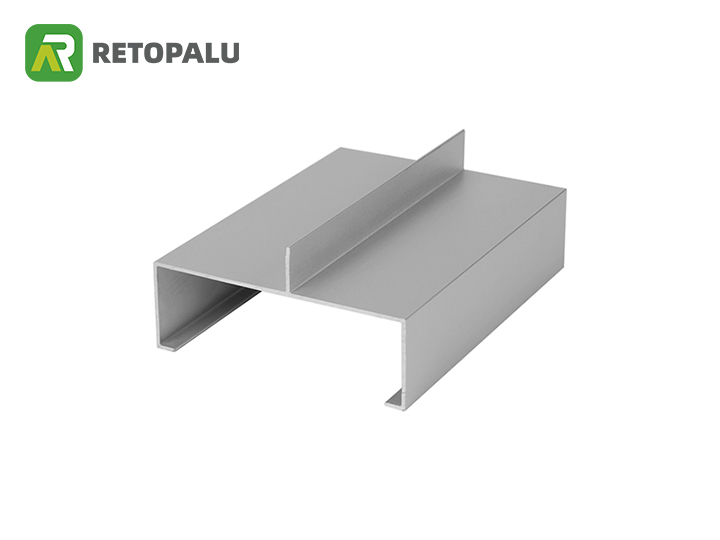

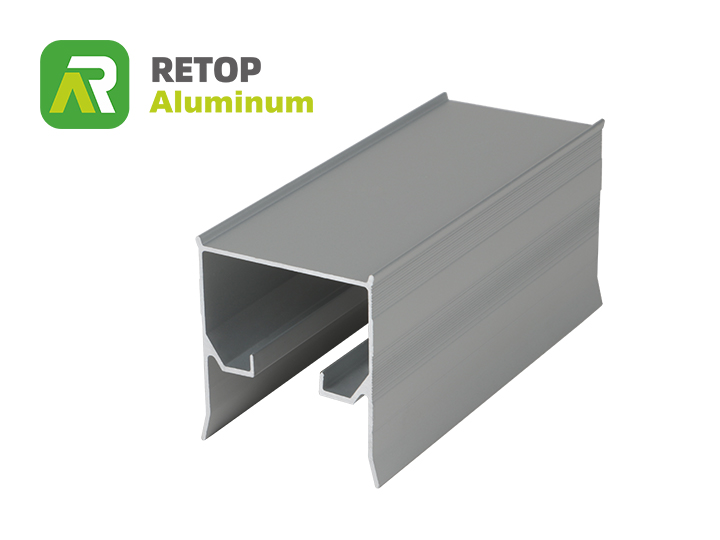

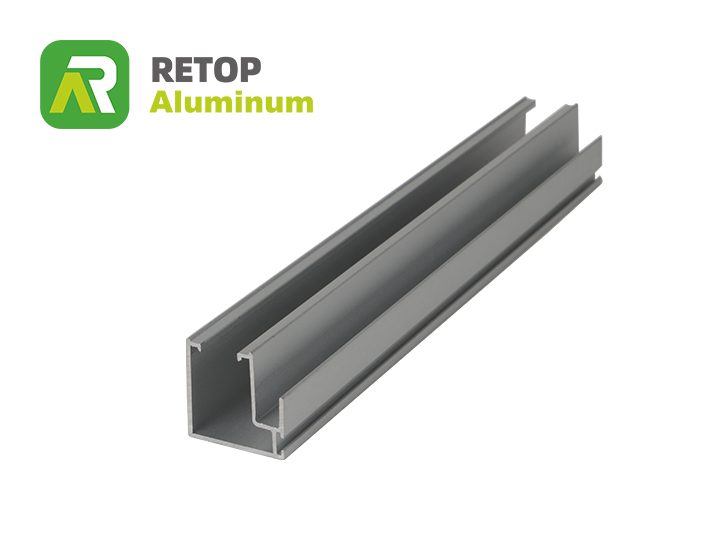

Anodized aluminum profiles are used in a wide range of applications, generally involving construction, transportation and electronics. For example, window frame aluminum profiles, door frame aluminum profiles, curtain wall aluminum profiles and so on. Its surface treatment can increase corrosion resistance and aesthetics, and is suitable for various architectural styles. Body structure, doors, windows and other parts. Its lightweight and high-strength characteristics help improve vehicle performance. And electronic products generally refer to electronic product shells, radiators and other parts.

Advantages of anodizing for aluminium profiles

1. Improvement of corrosion resistance

In the anodic oxidation process, the surface of the aluminum material will form a layer of oxide film. This layer of oxide film will determine the strength of corrosion resistance of aluminum materials. The thicker the oxide film, the stronger the corrosion resistance of the aluminum profile. Because the thick aluminum oxide film will help the aluminum profile to resist moisture, oxygen and other chemicals in the environment.

2. Improve abrasion resistance

Anodic oxidation forms a film that not only strengthens the hardness of the aluminum profile, but also protects the aluminum profile from the cuts and knocks of other objects.

3. Surface coloring

Anodic oxidation can form various colors on the surface of aluminum profiles. Generally the color of anodic oxidation coating is silver white, black, bronze, champagne and so on. This is because of the non-metallic characteristics of the anodized coating. Nowadays, many aluminum profile manufacturers can customize the desired color according to the customer’s demand.

4. Electrical insulation

The anodizing process involves placing the aluminum profile in a sulfuric acid solution. The oxide layer formed during this process is insulating, so it protects the aluminum profile from electrochemical reactions with other metals. This also makes anodized aluminum profiles more energy efficient.

5. Environmentally friendly

Compared with other surface treatment methods, the reaction process of anodizing is more environmentally friendly and has less impact on the environment. And the aluminum profiles can be recycled all the time.

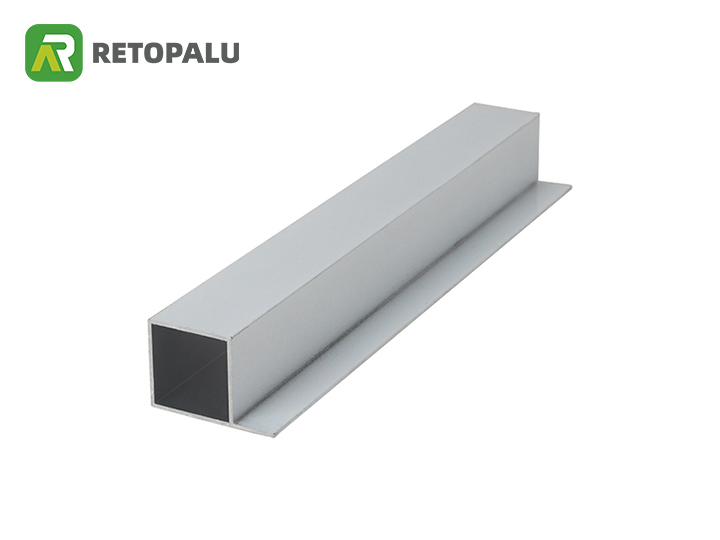

Retop-your best anodized aluminum profiles manufacturer

Founded in 2003, Retop has 20 years of manufacturing experience. We have customers all over the world. We produce aluminum profiles for many different areas. For example, in the architectural, decorative and industrial sectors. In addition to the usual aluminum profiles, we also provide customized services and further processing services. We are committed to providing our customers with aluminum profile products that meet their needs.

Regarding the surface treatment, we can provide such as anodizing, power coating, wood grain transfer and sandblasting. We have 2 anodizing production lines which can do up to 8 meters. The high quality finished anodized aluminum extrusions have gained many customers’ favor. We welcome you to inquire and visit our factory anytime!

To summarize! Anodized aluminum extrusions has many advantages, and people apply him more and more widely. If you need anodised aluminium profiles, please contact us, we will provide you with relevant product information!