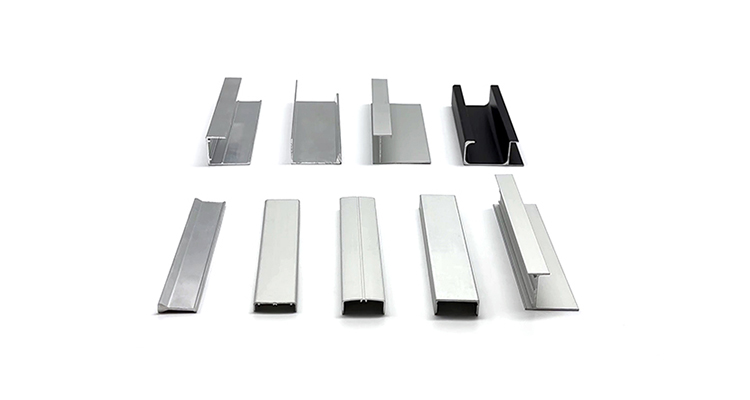

Aluminum Slim Partition Profiles for Office Cabin

Name: Aluminum Slim Partition Profiles for Office Cabin

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Slim Partition Profiles for Office Cabin

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Aluminum Slim Partition Profiles are specialized structural components used to create modular partition systems in workplaces. Made from high-quality aluminum alloys, these profiles offer durability, lightweight construction, and corrosion resistance. They provide a sleek and modern appearance while ensuring stability and ease of assembly.

We are a professional aluminum profile manufacturer and supplier with 21 years experience in factory extrusion, surface treatment and CNC machining. If you are looking for a long-term aluminum supplier, trust me! You have found the perfect business partner.

Aluminum Slim Partition Profiles are widely used in office cubicles, conference rooms, and workspace dividers, allowing for flexible space customization. They can support glass, wood, or composite panels and often come with anodized or powder-coated finishes for enhanced aesthetics and longevity. Their modular design enables quick installation and reconfiguration, making them a preferred choice for dynamic office environments.

| Name | Aluminum Slim Partition Profiles for Office Cabin |

| Brand | Retop |

| Category | Aluminum extrusion |

| Material | Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available |

| Temperament | T5-T8 |

| Length | As per drawing |

| Shape | Customized |

| Finish | Powder coating; also available polished, anodized, sandblasted, electrophoresis |

| Color | Silver, Black, Gold, Champagne, Bronze, Red. Blue, we can customize the color according to customer’s sample |

| Guarantee | BV, TUV, ISO |

| Standard | Medium and high quality |

| MOQ | 500KGS per piece |

| Application | Office |

| Deep processing | Cutting, drilling, machining, punching, bending, tapping, etc. |

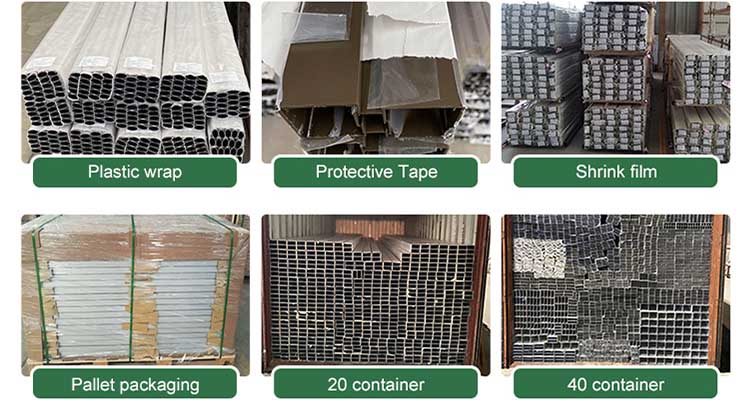

| Package | Inside with protective film, plastic shrink wrap or PE foam. Outside with box, carton or wooden frame, or customized. |

| Lead time | 12-18 days for mold development and sample molding, then 25-30 days for production cycle after receiving buyer’s deposit. |

We offer a variety of surface finishes for profiles. Anodized, powder coated, wood grain, electrophoresis, polished, brushed and many other colors are available.

The variety of colors and styles can meet different types of customer needs. A variety of finishes and colors are available, including anodized, powder coated, wood grain, electrophoresis, polished, brushed and more.

We also pay great attention to details and use professional packaging materials and transportation methods to provide customers with safe and reliable delivery services. Meanwhile, Retop Aluminum has an efficient and professional after-sales team, which always pays attention to the operation of the products and provides customers with technical support and problem solving in time.

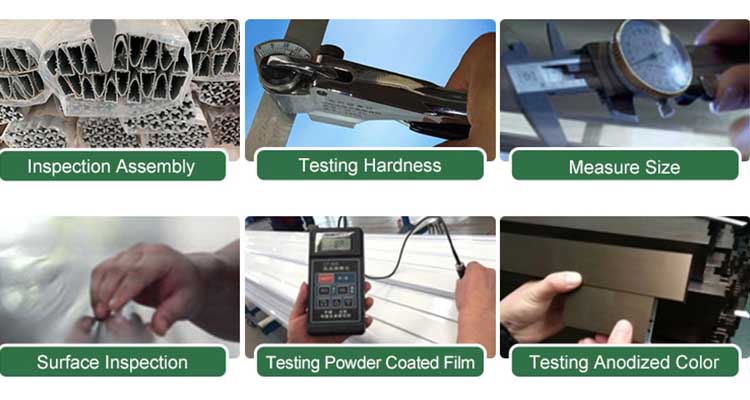

We always strictly control the quality management during the production process of our products to ensure that all the indexes of our products are in line with international standards and customer requirements. 100% online quality control and final inspection before delivery. There shall be no scratches, deformation or bruises within one meter of the product surface. And the samples are treated with even coloring surface.

Q1: Can I get some samples of profiles from your company?

Yes, we can provide free samples according to your drawings, but the shipping cost is paid by our customers.

Q2: How to confirm the quality of the product before formal order?

After the customer pays for the mold, we will make samples based on the drawing confirmed by the customer. Once the customer receives the samples from us and confirms them, we start to produce the products according to the contract.

Q3: Are there any discounts?

There are different discounts for different quantities.

Q4: How do you handle quality complaints?

First of all, our quality control reduces quality problems to close to zero. If the quality problem is really caused by us, we will replace the product or refund your loss for free.

Name: Aluminum Powder Coating Roller Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Zebra Blinds Bottom Rail Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminium Curtain Track Zebra Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Blind Roller Tube Aluminium Pipe Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Extruded Curtain Bottom Rail Section

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Office Partition Aluminum Extrusion

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8