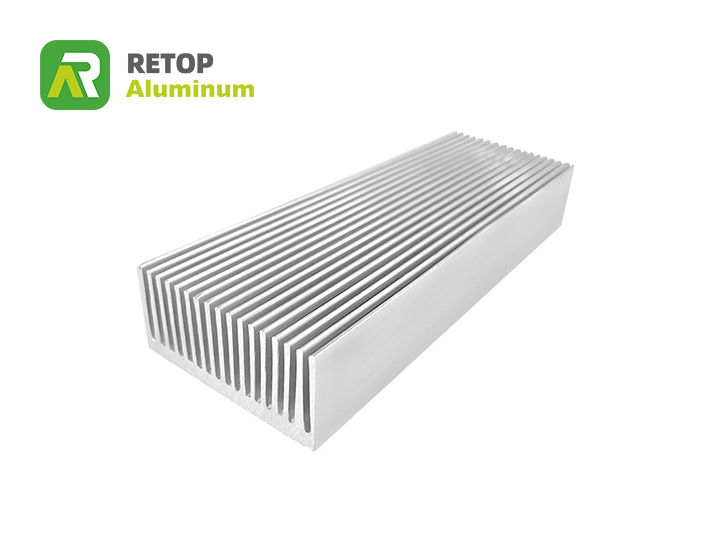

Aluminium heat sink technology and application

Aluminium heat sinks are high-quality heat dissipation products. Its applications are very extensive. It is applied in various industries and is closely related to our daily lives. The following is a brief explanation of the process flow and application of aluminum profiles for radiators:

Manufacturing process of aluminium heat sink

1. Selection of raw materials

The first step in making aluminum profile heatsinks is to select high-quality aluminum alloys. Aluminum alloy is a metal with light weight and high conductivity. It ensures effective heat transfer while maintaining structural integrity.

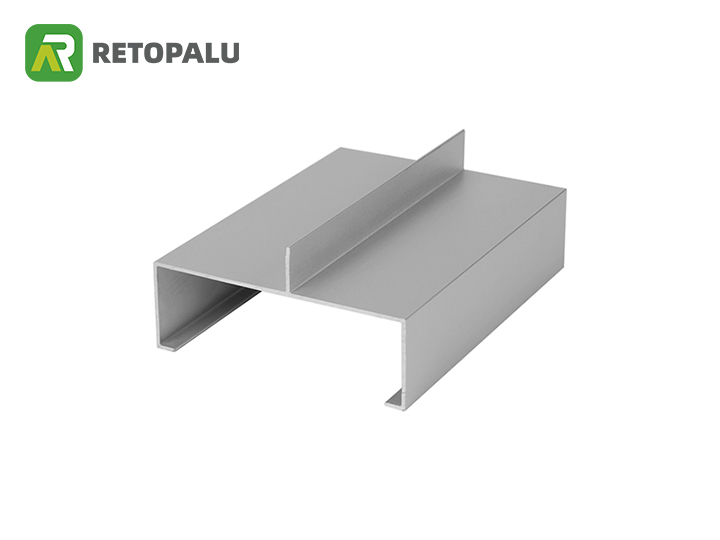

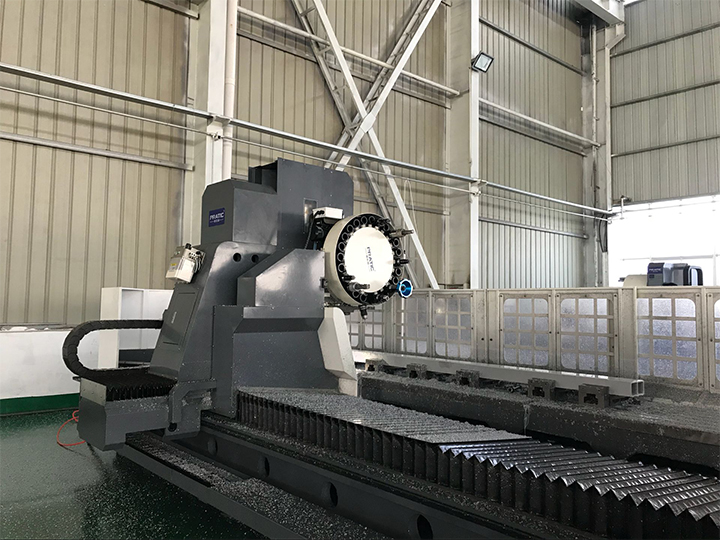

2. Squeeze

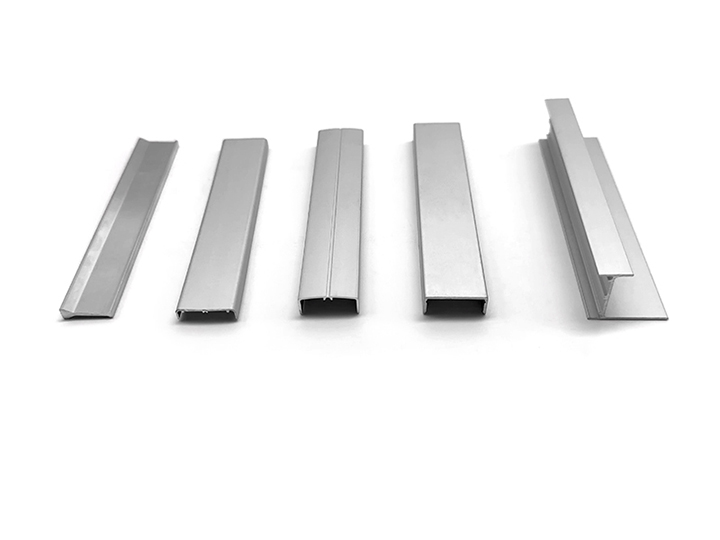

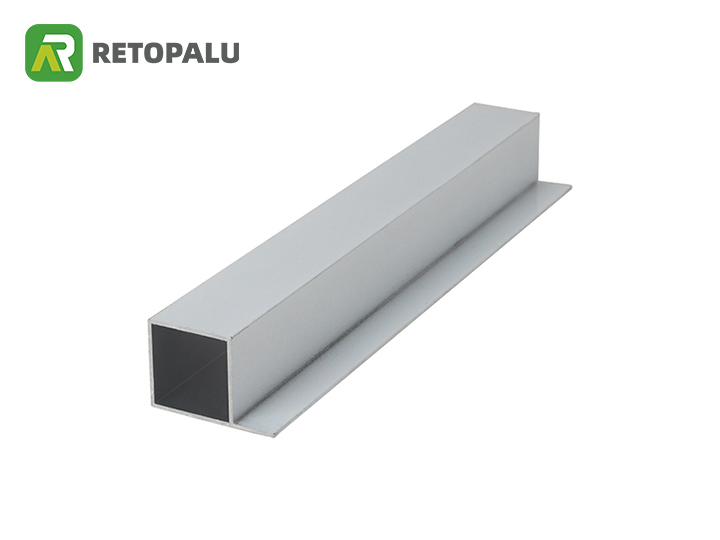

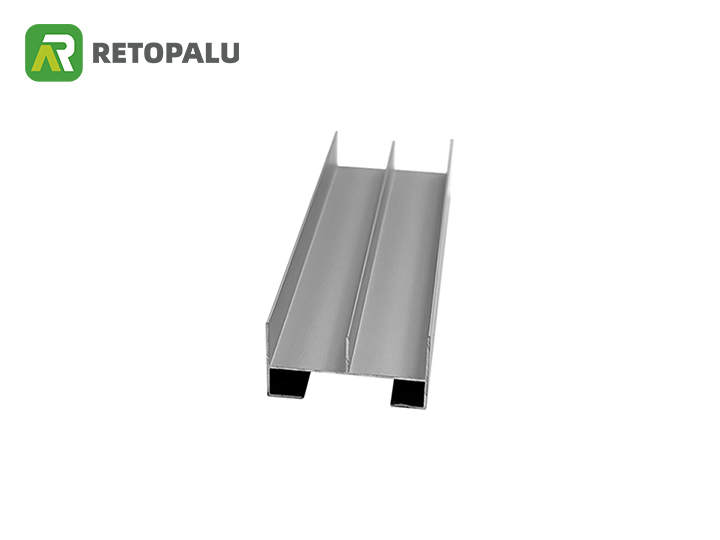

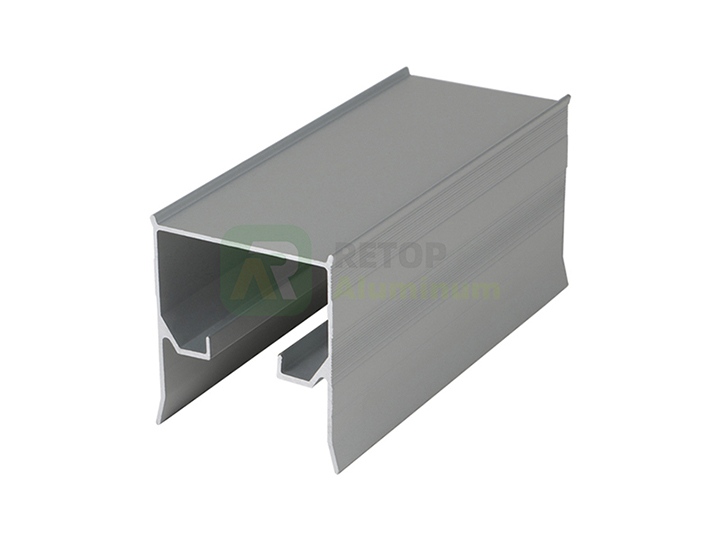

The most common method of manufacturing aluminum profiles is extrusion. During the extrusion process, the selected aluminum alloy is heated and forced through the forming mold to form a specific shape. The extruded profiles are then cooled and cut into appropriate lengths.

3. Surface treatment method

Many aluminum profiles undergo surface treatment after production. Aluminum profiles that have undergone surface treatment can enhance their anti-corrosion performance while also making them more aesthetically pleasing. Nowadays, many factories use anodizing, powder coating, and painting methods for surface treatment.

4. Assembly

After all individual aluminum profiles are prepared, they are assembled into the final structure. Assembly is based on the design and application of profiles.

Usage of heat sink extrusion profiles

1. House heating system

Aluminium heat sinks are widely used in residential heating systems due to their excellent thermal conductivity and lightweight properties. They can effectively heat and distribute heat throughout the entire space, providing cost-effective and environmentally friendly heating solutions.

2. Automotive industry

In the automotive industry, aluminum radiator profiles are commonly used for engine cooling systems. Lightweight structure helps improve fuel efficiency. High thermal conductivity ensures effective heat dissipation and prevents engine overheating.

3. Industrial cooling applications

Heat sink extrusion profiless are often used in industry to cool applications.

4. Solar thermal system

In solar thermal systems, aluminum radiators play a crucial role in absorbing and transferring solar energy to add hot water or air. The lightweight properties of aluminum make these radiators suitable for roof installation and various solar applications.

5. Architectural and interior design

Aluminium heat sinks are favored by architects and interior designers for their fashionable and modern appearance. They are mostly used as decorative elements and heating solutions for commercial buildings, hotels, and other public spaces.