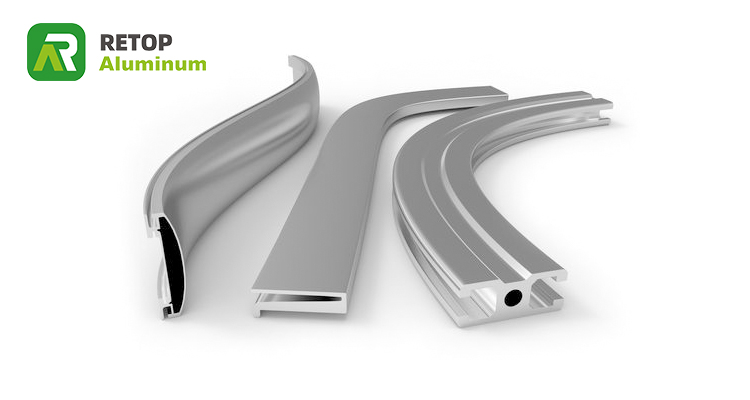

CNC aluminum curved profile tubes

Item: CNC Aluminum Curved Profiles Tubes

Temper:T5-T8

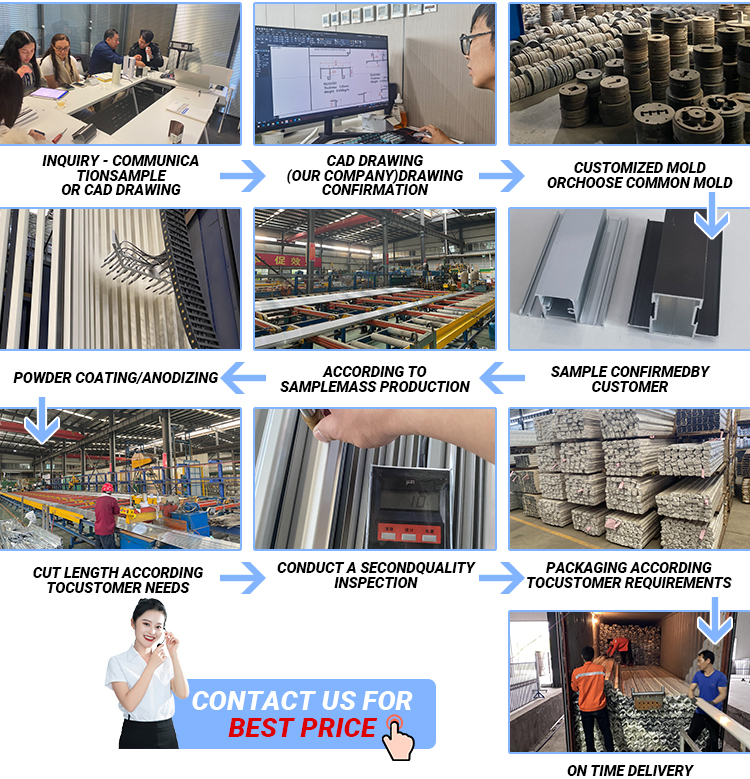

Process Flow:Mould Development–Aluminium Billets—Heating Up—Moulding with Raw Aluminium—Surface Treatment and Color

Shape:Customization

Item: CNC Aluminum Curved Profiles Tubes

Temper:T5-T8

Process Flow:Mould Development–Aluminium Billets—Heating Up—Moulding with Raw Aluminium—Surface Treatment and Color

Shape:Customization

CNC aluminum curved profiles tubes are specialized profiles made of aluminum that are bent into specific shapes using computer numerical control (CNC) machines.

CNC aluminum curved profiles Tubes are a versatile and practical choice for a variety of industries. Their production process, structural design and many benefits make them an attractive choice for engineers, architects, designers and more.

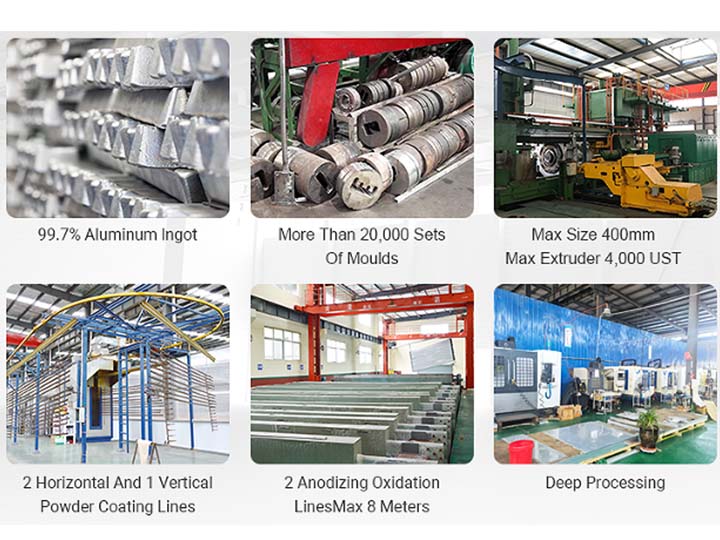

We are one of the professional aluminum bending and drawing manufacturers in China with more than 20 years of rich experience. If you are looking for a long-term aluminum profile supplier, we are your best choice.

| Item | CNC Aluminum Curved Profiles Tubes |

| Temper | T5-T8 |

| Process Flow | Mould Development–Aluminium Billets—Heating Up—Moulding with Raw Aluminium—Surface Treatment and Color |

| Characteristic | 1.Neat and beautiful fine lines on the surface. 2. National standard aluminum billets are adopted. 3. With our even anodizing process, which is adapted for protecting the surface. 4. Small order is acceptable. 5. Customized Extrusion as per your drawing. |

| Application | Building, Decoration |

| Shape | Customization |

| Surface Treatment | Mill finished, Anodized, Power coating, Sand Blasting, Electrophoresis, Brushed, Polishing, etc |

| Color | Silver, black, gold, Champagne, Bronze, red, Blue; we can customize the colors based on customers’ samples |

| Deep processing | Cutting, drilling, machining, punching, bending, tapping and so on |

| Guarrantee | ISO:9001, SONCAP , BV Certificate, TUV, SGS, or customers’ Certificate Available |

| MOQ | 500KG for each profile |

| Delivery Time | Mould developing and sample conformation is 12-15 days, then production duration is 15-25 days after receipt of deposit from buyer |

| Free Sample | 1-3 days can be sent |

The production process of CNC aluminum curved profiles begins with the selection of high quality aluminum. The aluminum is then cut to the desired length. The next step is to create a CAD design of the contoured curve shape. This design is then fed into a CNC machine, which uses cutting tools to bend the aluminum into the exact shape of the design. The CNC machine also cuts and finishes the profile to ensure precise dimensions and a smooth surface finish.

The structural design of CNC aluminum curved profiles is one of their main features. They are designed to provide superior strength and durability while being lightweight. The curved shape of the profile allows it to resist bending and flexing under heavy loads. They also offer excellent corrosion resistance, making them ideal for use in harsh environments exposed to moisture and chemicals.

Product Features

CNC aluminum curved profiles tubes are lightweight and easy to transport and install. They are also extremely durable and long lasting, making them a cost-effective solution for many applications. Their excellent corrosion resistance ensures that they continue to perform well even in harsh environments. In addition, they can be customized to meet specific design requirements, offering unlimited design possibilities.

CNC aluminum curved profiles tubes are widely used in the automotive, aerospace, construction, and furniture industries. They are particularly useful in applications that require complex shapes, such as in the construction of curved walls, circular staircases, and round structures. They are also used in the manufacture of furniture, lighting fixtures and decorative elements.

4. Mold customization

5. Aluminum extrusion

6. Surface treatment

7. CNC Aluminum

8. Strict quality control system, one by one inspection, to ensure excellent quality.

9. Timely troubleshooting and problem solving, if the product is defective due to manufacturing problems, we will reproduce and compensate.

From aluminum bar casting, mold development, profile extrusion, uniform sandblasting, anodic oxidation, single and double salt coloring, electrophoretic painting, multi-color powder coating, wood grain simulation, energy-saving and heat-insulating aluminum profiles, and even precision testing, Zoomlion adopts the more advanced international technology, which makes the products highly automated.

It is an extensive set of aluminum solutions that can be customized at will for the implementation of a wide range of architectural designs.

Name: Aluminum Powder Coating Roller Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Zebra Blinds Bottom Rail Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminium Curtain Track Zebra Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Blind Roller Tube Aluminium Pipe Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Extruded Curtain Bottom Rail Section

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Office Partition Aluminum Extrusion

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8