Aluminum Extruded Anodized Aluminum Profile

Grade of oxide film thickness: AA10

CASS Test: 16h, Grade≥9

Alkali Spotting: ≥50

Falling sand test wear coefficient g/um: ≥300

Grade of oxide film thickness: AA10

CASS Test: 16h, Grade≥9

Alkali Spotting: ≥50

Falling sand test wear coefficient g/um: ≥300

Source Aluminum Extruded Anodized Aluminum Profiles manufacturer and supplier: small material oxidation, ultra-thin material dyeing, anodic oxidation, triacid oxidation, polished anodic oxidation, bright oxidation, mirror polishing oxidation, bathroom polished aluminum alloy profiles.

We are an anodized aluminum profile manufacturer with 20 years experience and over 60,000 molds. We can customize all kinds of anodized aluminum profiles, including aluminum angles, aluminum angle bars, aluminum channels, aluminum profiles, aluminum profiles, aluminum tubes and so on. This page only shows hot anodized finishes. If you want to know more information or have specific needs, please directly send an online inquiry for a detailed catalog.

RETOP aluminum profile anodized profiles with almost invisible mechanical lines on the surface are beautifully and finely sandblasted. The anodized thickness is between 10 and 13 μm and the surface is hardly scratched. Tiny scratches can also be easily removed. However, other profile products of the same color on the market are easily bruised due to their small thickness, and the scratches on the surface are also difficult to remove.

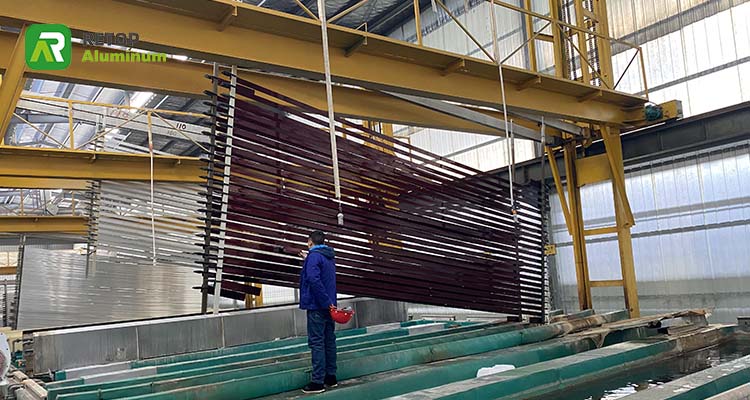

The anodizing process involves the use of an electrolytic solution to form a layer of oxide on the surface of an aluminum extrusion. This process creates a hard, durable and corrosion-resistant coating on the aluminum extrusion.

Anodizing is a surface treatment process that enhances the properties of aluminum, including scratch resistance, abrasion resistance and corrosion resistance. Anodizing also enhances the aesthetics of aluminum profiles by providing a range of colors and finishes that can be applied to the anodized layer.

Extruded anodized aluminum profiles are commonly used in a variety of applications, including architectural, automotive and industrial applications. They are particularly suitable for applications that require a high level of corrosion resistance, such as marine applications, or a high level of wear resistance, such as machinery and equipment. The anodizing process can be applied to all types of aluminum profiles, including standard shapes, custom shapes and complex profiles. The process is highly customizable, allowing the creation of profiles with a wide range of colors and finishes. Anodizing is a cost-effective way to enhance the performance and appearance of aluminum profiles, making it a popular choice for many applications.

RETOP extruded anodized aluminum profile finishes are available in a variety of standard finishes to help create the exact look you need.

Aluminum is typically exposed to a variety of corrosive conditions (weather, coastal areas, etc.), so RETOP pioneered a special pre-anodized finish that significantly reduces “filiform” corrosion.

Inspired by the beauty of nature, RETOP offers a wide range of colors designed to create the perfect color scheme.

Please note:

Due to lighting, electronic device monitor resolution and other factors, there will be color differences between the pictures and the real thing. These colors are for reference only. To ensure optimal accuracy, please request a free sample to test your color choice at home.

Combine brushed with unlimited colors to create long-lasting architectural solutions with unparalleled style and quality.

The product has high transparency, high full shielding rate, special luster and transparency, high three-dimensional effect after painting; good leveling, strong paint film feeling, thin and smooth hand feeling. And high hardness, when the temperature of 180 ℃ baking 30min, hardness up to 4-5H, wear-resistant, long service life. “The surface texture and delicate, non-stick oil, non-stick water, attached to the surface of the dust and stains can be restored to its original appearance with a light wipe.

Copper Accelerated Spray Acetate Spray Test (CASS) and Alkali Spot Test, abrasion resistance.

| Grade of oxide film thickness | corrosion resistance | Abrasion Resistance | ||

| CASS Test | Alkali Spotting | Falling sand test wear coefficient g/um | ||

| Time (h) | Grade | |||

| AA10 | 16 | ≥9 | ≥50 | ≥300 |

| AA15 | 32 | ≥9 | ≥75 | ≥300 |

| AA20 | 56 | ≥9 | ≥100 | ≥300 |

| AA25 | 72 | ≥9 | ≥125 | ≥300 |

1.Material: We use 100% original top grade AA quality 6063 Plus aluminum ingot to achieve the shiniest surface even in milling process, no mechanical lines and sand entrapment.

2.Technical process: Anodic oxidation film thickness: (12–15μm) using top wet phosphoric acid chromaticity ≤ (s04ppm ≤ 0.011000.02200) to achieve the effect of automatic repair after scratches.

| Oxide film thickness | Minimum mean film thickness (um) | Minimum local film thickness (um) |

| AA10 | 10 | 8 |

| AA15 | 15 | 12 |

| AA20 | 20 | 16 |

| AA25 | 25 | 20 |

3.Anodic oxidation process: adopt German KRAUTZBERGER sand blasting machine for no mechanical lie treatment, which is seldom realized in aluminum industry.

4.Appearance Guarantee: Our SACTT446 anodic oxidation tank converts ammonium sulfite into ammonium sulfate to ensure that the surface color never fades.

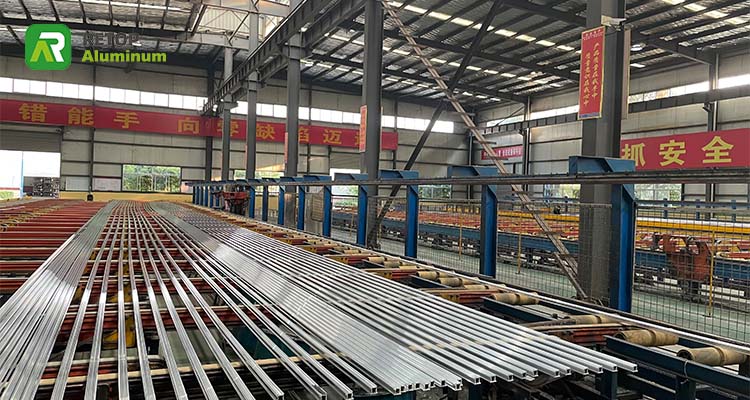

5.Extrusion precision: We use YW-660UST extruder to ensure that the precision tolerance is kept at ±0.3.

The surface has neat and beautiful fine lines. National standard aluminum billet is used. By using our uniform anodizing process to protect the surface, the color of our anodized profiles suffers minimal damage compared to other profiles of the same color on the market.

We have over 60,000 dies in stock. If our aluminum extrusion anodized aluminum profiles are not suitable for you, you can provide us with your samples or technical drawings and we can extrude them according to your design. OEM and ODM services are always welcome.

1. 20 years of comprehensive aluminum manufacturing experience as a fully integrated aluminum material supplier.

2. Own CNC machining plant to provide customized solutions for aluminum profile machining needs.

3. One-stop aluminum profile manufacturing services from design, engineering, extrusion, finishing and quality control.

4. Reasonable pricing strategy and high level quality assurance system to ensure customers get the best value proposition.

5. Professional overseas sales and technical teams to support customers in various international markets.

1. On-time delivery

We have enough production capacity to meet customer’s order requirements, logistics company will arrange for the

The orders are ready to be delivered to customers after the production is completed. Zhonglian all provide world-class products in a short time.

2. Quality Inspection

Professional design team participates in design, production and improvement, the optimal error range is within 1%. The products will pass the product quality inspection before delivery. Customers can personally inspect the goods or entrust professional organizations to inspect the goods.

3. Customized Packaging

Everything is in the details. We want to make sure you receive the best quality goods. Taking extra proper precautions

Packaging aluminum to protect the finish is just one more step retop takes to ensure quality.

In a project, we always provide our customers with a comprehensive aluminum extrusion solution. Not only do we work with our clients from the design stage, but we also strive to provide the highest quality products during the production and manufacturing stages. Our professional team provides one-stop service to our clients, saving them time and effort throughout the process while ensuring the highest quality and reliability. Our solutions have been highly recognized and appreciated by our clients, and we have successfully provided reliable aluminum extrusion services to hospitals. When you work with us, you can count on our expertise and quality assurance.

We are in the business of making our customers happy. Customers rave about our aluminum extruded anodized aluminum profiles.

RETOP was founded in 2003 with the belief that quality products and exceptional customer service will stand the test of time. More than 20 years later, we still believe that customer satisfaction drives the way we do business. Over the years, we have worked with overseas customers in over 70 countries and 200 locations.

Name: Aluminum Powder Coating Roller Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Zebra Blinds Bottom Rail Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminium Curtain Track Zebra Blinds Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Blind Roller Tube Aluminium Pipe Profiles

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Aluminum Extruded Curtain Bottom Rail Section

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8

Name: Office Partition Aluminum Extrusion

Brand: Retop

Category: Aluminum extrusion

Material: Aluminum alloy (6063, 6061, 6464, 6082), 1000, 3000 series available

Temperament: T5-T8