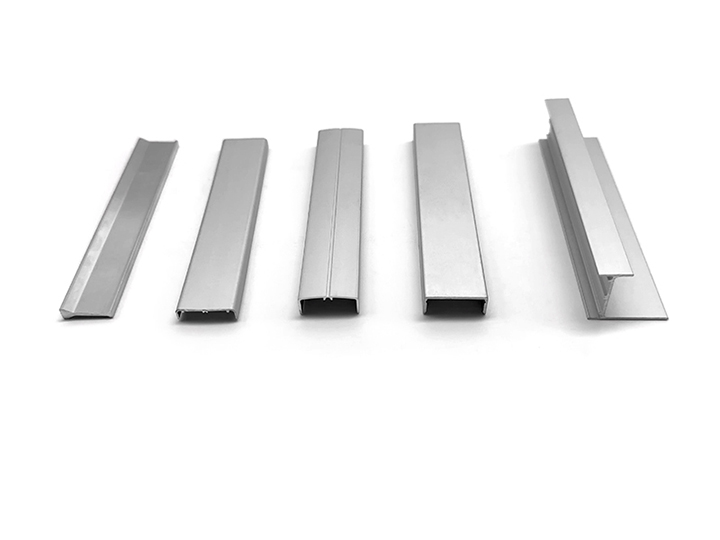

Custom aluminium profiles from Retop

Retop has strong ability to support custom aluminium profiles. Custom aluminum profiles are now a widely business that many aluminum profile manufacturers have to deal with. As the application range of aluminum profiles continues to expand, there is now a diverse demand for aluminum profiles. Aluminum profiles with general specifications can no longer meet the needs of customers. There are more and more demands for customized aluminum profiles.

Until now, Retop has received many requests for custom aluminium extrusions. And we have produced customized aluminum profiles according to customers’ needs. Welcome you to consult us at any time!

The specific steps of customized aluminum profiles

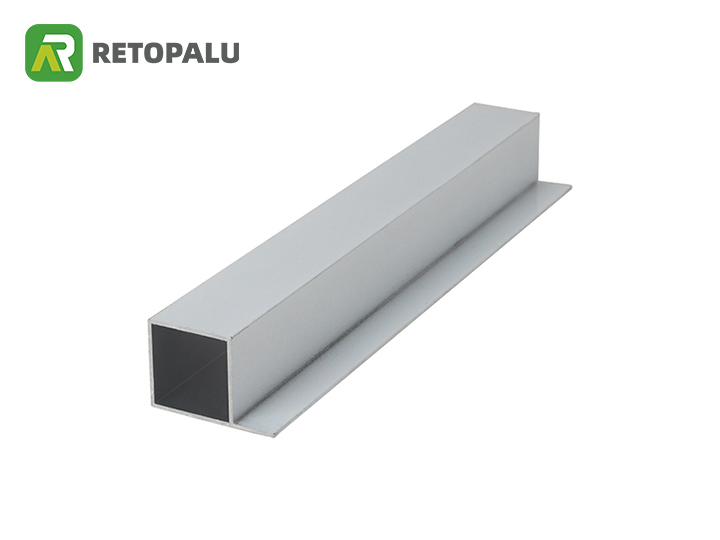

1. First of all, we need to understand the product parameters in detail according to the customer’s needs, such as shape, structure, size, mechanical properties, configuration, etc..

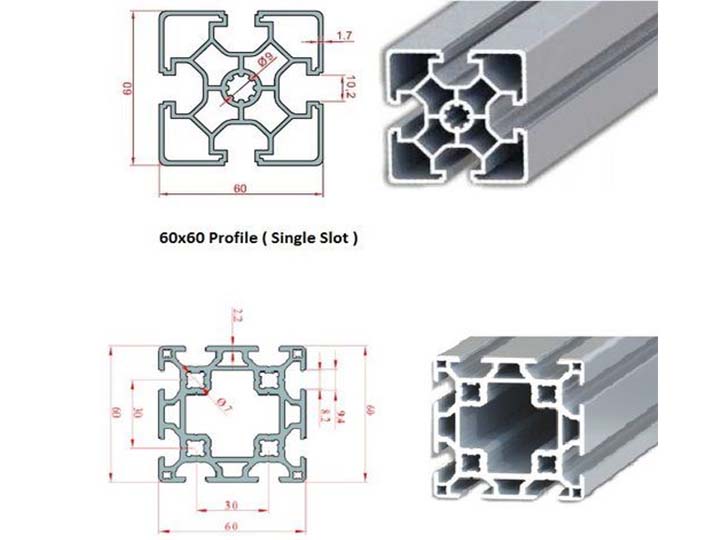

2. Then according to the above information, technicians start to issue design drawings and technical parameters.

3. The designed drawings need to be confirmed by both parties, the purpose is to confirm the implementation of standards and test standards.

4. After confirming that the drawings are completely correct, the manufacturer will extrude samples according to the mold. These samples will be confirmed by the customer.

5. After the customer confirms that the samples are correct, the aluminum extrusion manufacturer can proceed to mass production.

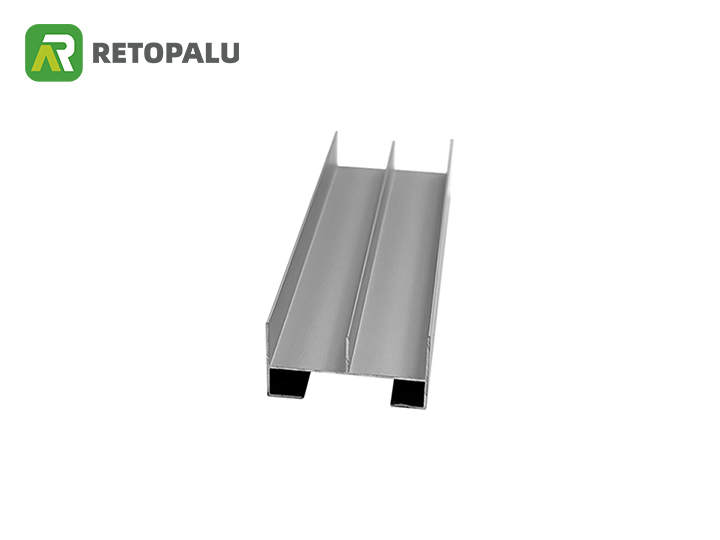

Precision control of custom aluminum extrusion

The precision control of custom aluminum extrusion generally has strict requirements for extrusion equipment and extrusion dies. Generally the product precision control range is ±0.04mm.

1. The precision of mold design and its material process is the main factor that directly affects the quality and dimensional accuracy of custom aluminium extrusions. The choice of material for the mold must meet the requirements of high hardness, high temperature resistance and friction resistance.

2. The normal working environment temperature of the extrusion mold is about 500℃. Die material high temperature yield strength should not be less than 1200N/mm 2. Friction resistance at high temperatures is mainly reflected in the hardness and thickness of the nitrided layer. The general hardness of the nitrided layer should be above 1150HV, and the thickness should be between 0.25mm and 0.45mm. The precision change of the mold after nitriding should be controlled within 0.02mm.

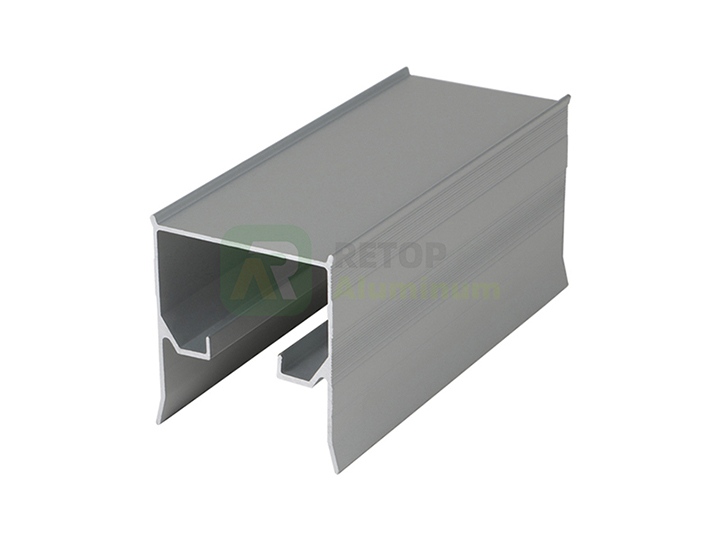

Custom aluminium extrusion cost

The cost of the mold is calculated according to the complexity of the mold, its specifications and cross-section size, and the tonnage of the extruder required. Meanwhile, the cost of the die will be refunded after the customer’s use reaches a certain level.