Effect of anodizing on aluminium extrusion profiles

Aluminium extrusion profiles have always been very popular. Mainly because of the advantages of aluminum profiles such as corrosion resistance, high hardness and easy processing. Generally, people do not use aluminum material directly. And the aluminum profile manufacturer will do the surface treatment after the aluminum material is formed. The surface treatment is generally anodized, power coating, sandblasted, wood grain transfer and so on. Among them, anodizing is the most common surface treatment.

What is the impact of anodizing on aluminium extrusion profiles?

- Increase corrosion resistance. The oxide film formed by anodic oxidation can increase the corrosion resistance of aluminum alloy, making it more resistant to the erosion of the external environment such as air, water and chemicals. This helps to extend the service life of aluminum alloy products.

- Improve abrasion resistance. Aluminum profile matts are particularly susceptible to scratching and abrasion. And the hardness of aluminum alloys cannot be compared with that of steel. The surface of the anodized industrial aluminum profile is very hard. And the hardness of the oxide film can reach 300 HV, so it is very wear-resistant and not easy to be scratched.

- Stronger decorative. Before the anodic oxidation sealing of profile extrusion aluminium, there will be many dense pores on the surface. So the aluminum profile can easily adsorb some metal salts or dyes, which makes the surface of aluminum products form rich.

- Improvement of lubrication performance: Some oxidation treatment methods can make the surface of aluminium extrusion profiles smoother, thus improving lubrication performance. This is especially important for mechanical parts that require low friction.

- Electrical insulation: Some types of oxide films can improve the electrical insulation properties of aluminum alloys for electronic and electrical applications.

- Increased hardness: The oxide film produced by anodizing can significantly increase the hardness of the aluminum alloy surface. Aluminum profiles will be more resistant to abrasion. This is particularly important for parts and products that are subject to frequent friction or physical wear.

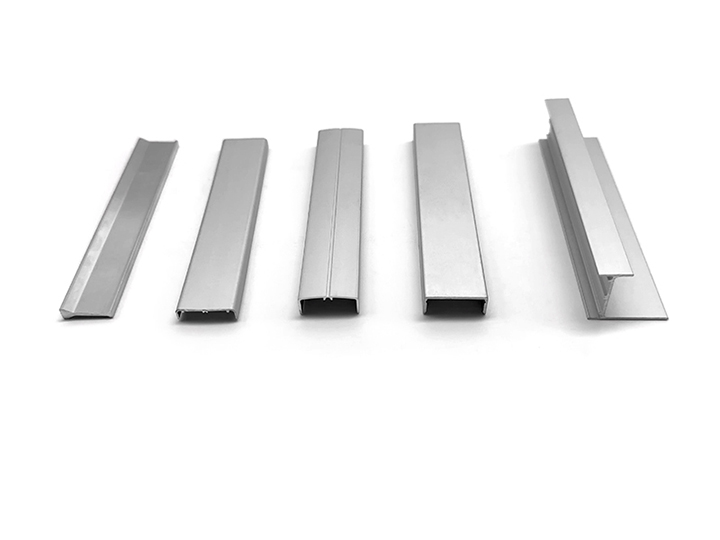

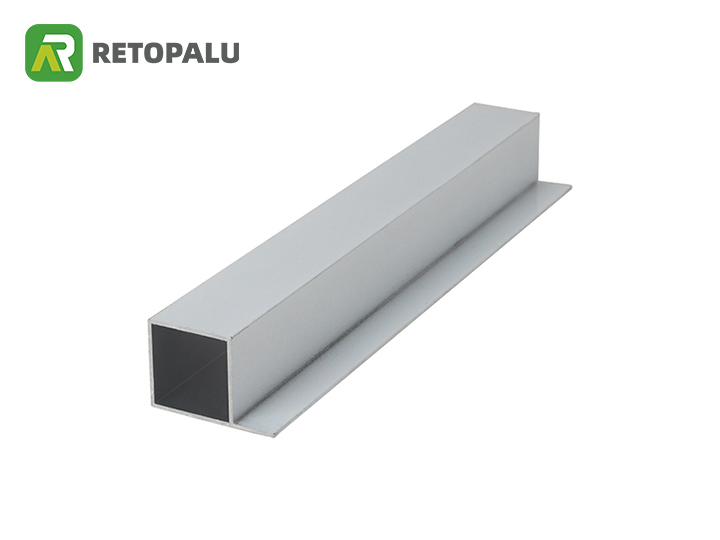

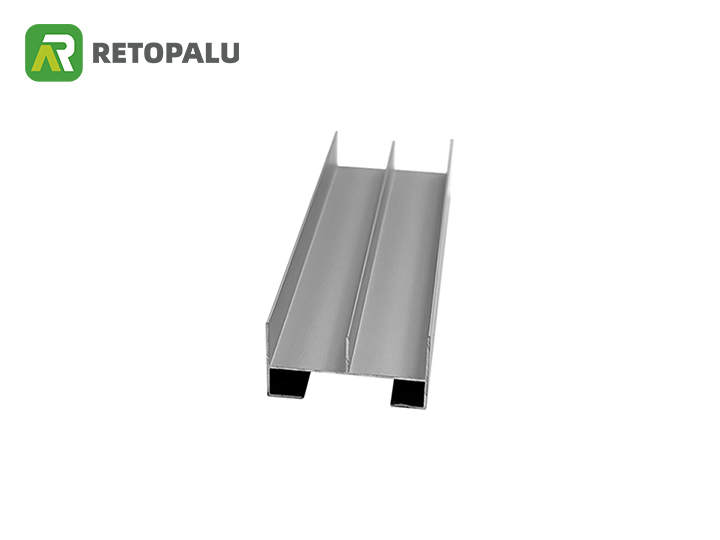

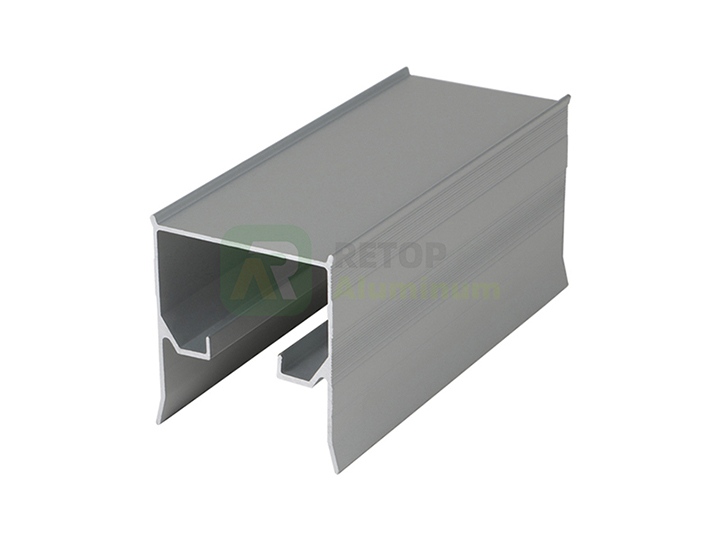

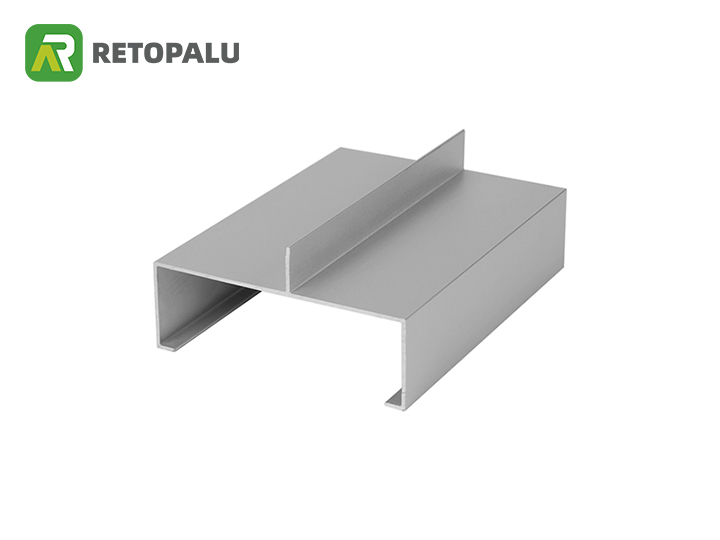

We produce aluminum profiles, for example, aluminum profiles for windows and doors, curtain wall aluminum profiles, aluminum profiles for curtain tracks, aluminum office partition profiles, etc. that can be anodized. We can also carry out surface treatments such as spraying, wood grain transfer, sandblasting, etc. according to customers’ needs.