Aluminium extruded profiles properties and uses

Aluminium extruded profiles 6063 is an aluminum alloy with magnesium and silicon as alloy elements. It usually has good processing properties, corrosion resistance, mechanical properties, and can be heat treated and welded.

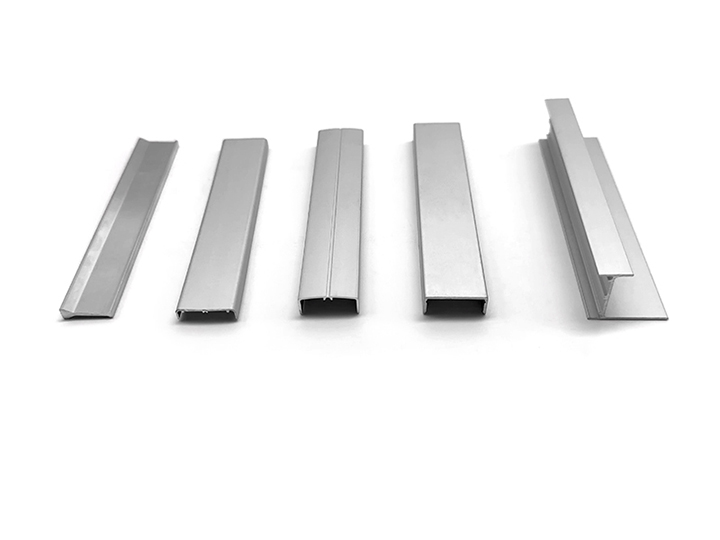

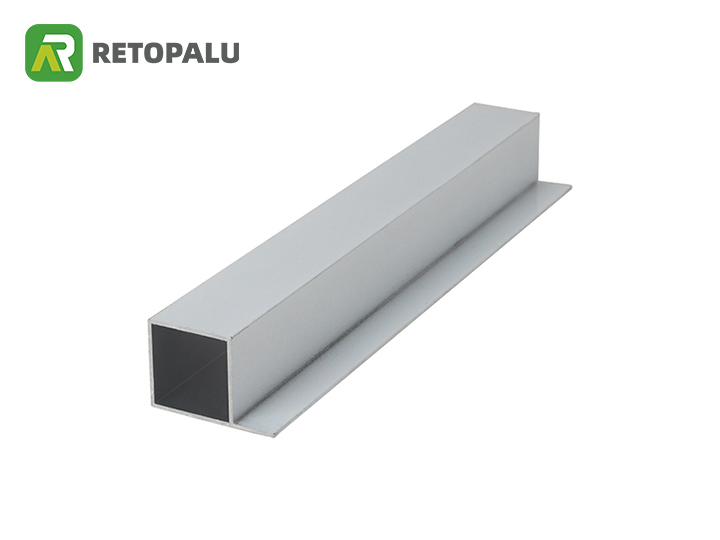

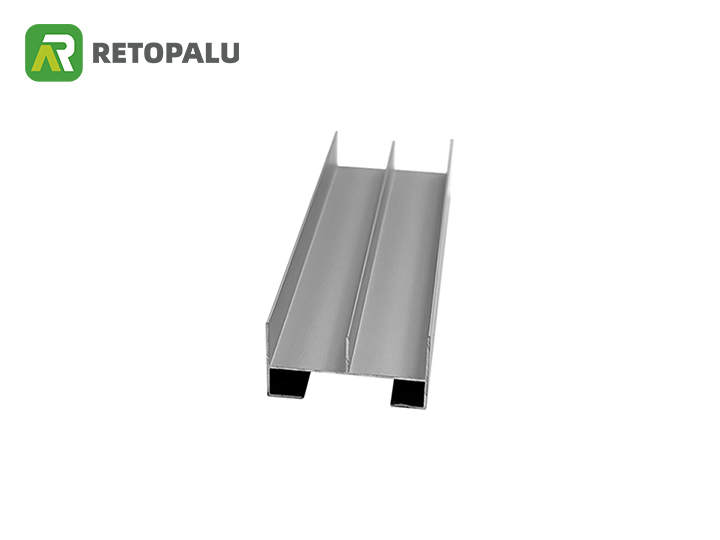

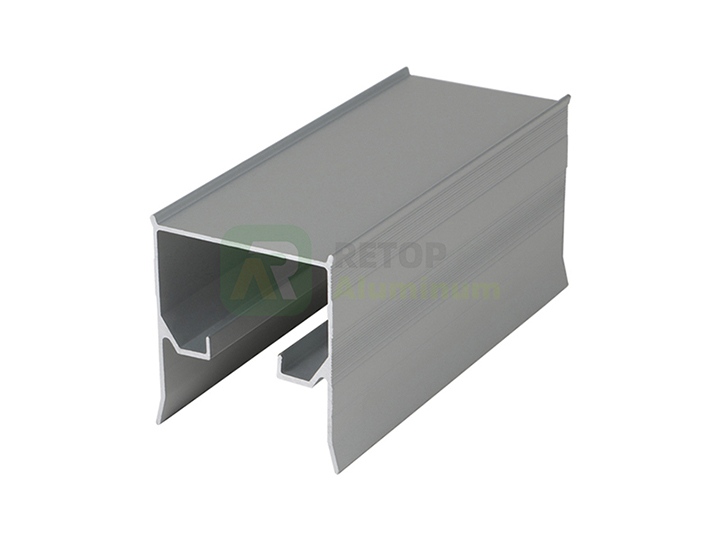

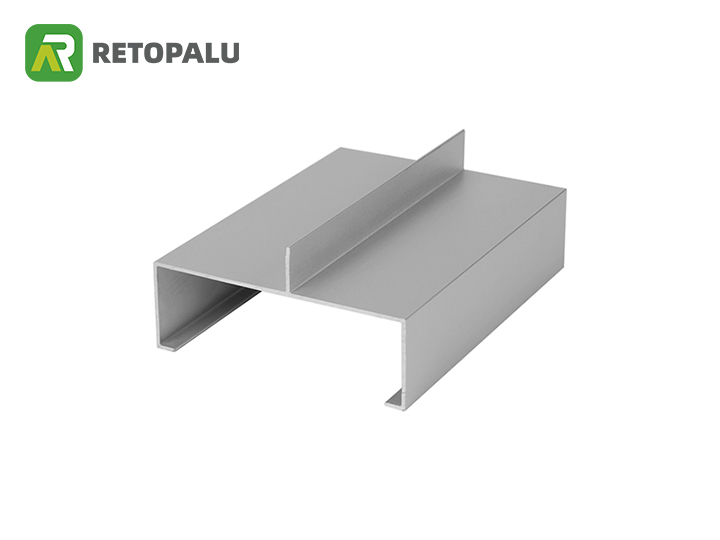

6063 is an aluminium extruded profiles material commonly used in aluminum extrusion. We can process it into various complex shapes. After treatment, the surface of aluminum 6063 is very smooth. It is therefore well suited for anodizing and is popular in architectural and decorative aluminum profiles. Often used to make door frames, window frames, curtain walls, curtain tracks, wardrobes, cabinets, etc.

Mechanical properties of 6063 aluminium extruded profiles

The mechanical properties of 6063 extrusion profile aluminium depend largely on the tempering or heat treatment of the material.

The commonly used aging states of 6063 aluminum alloy are T5 and T6. Among them, T5 is air-cooled. The air-cooled aluminum profile has small changes, is easy to control, and has average hardness. T6 is water-cooled. The aluminum section is easy to deform and difficult to control, but it has high hardness. Therefore, if you need aluminum extrusions with relatively high strength and force-bearing capacity, you can choose T6-treated aluminum profiles. General aluminum profiles can be used in T5 condition.

Uses of 6063 extrusion profile aluminium

6063 extrusion profiles are widely used in building curtain walls, door and window frames, curtain tracks, cabinets, wardrobes, as well as household items, furniture aluminum profiles, assembly line aluminum profiles, aluminum profile shells, aluminum radiators, etc.

Welding of 6063 extruded profiles aluminium

6063 aluminium profiles are highly weldable and are welded using tungsten inert gas. Generally speaking, after welding, the performance near the weld will be close to the 6063-0 state, and the strength may drop by up to 30%. However, this material can be reheat treated to restore the entire part to a higher tempered state.