Difference Between 6061 And 6063 Aluminum Profiles

6061 and 6063 are two common grades of aluminum alloys used to manufacture extruded aluminum profiles, which are used in a wide range of applications such as construction, transportation, electronics, and consumer goods.

The main difference between 6061 and 6063 aluminum profiles is in their chemical composition and physical properties, which affect their suitability for different applications.

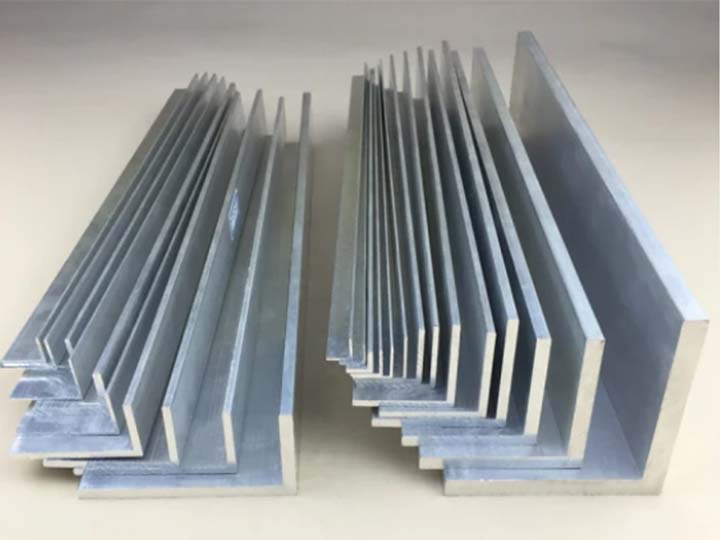

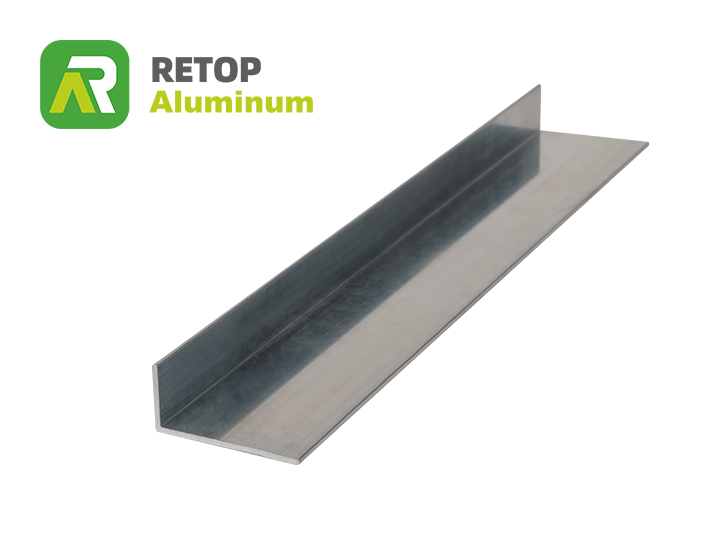

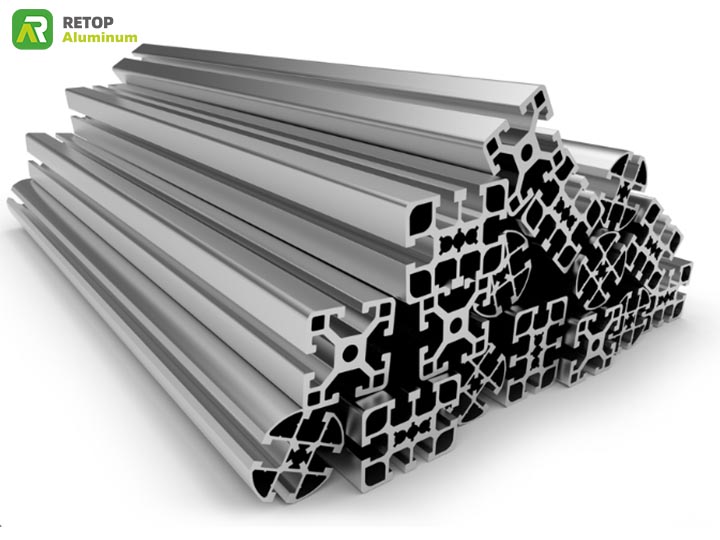

6061 aluminum profiles have higher strength and toughness than 6063 aluminum profiles, making them more suitable for heavy-duty applications such as structural components and machined parts. They also have good corrosion resistance and are easily welded and formed. However, 6061 profiles may be more expensive than 6063 profiles due to their higher manufacturing costs.

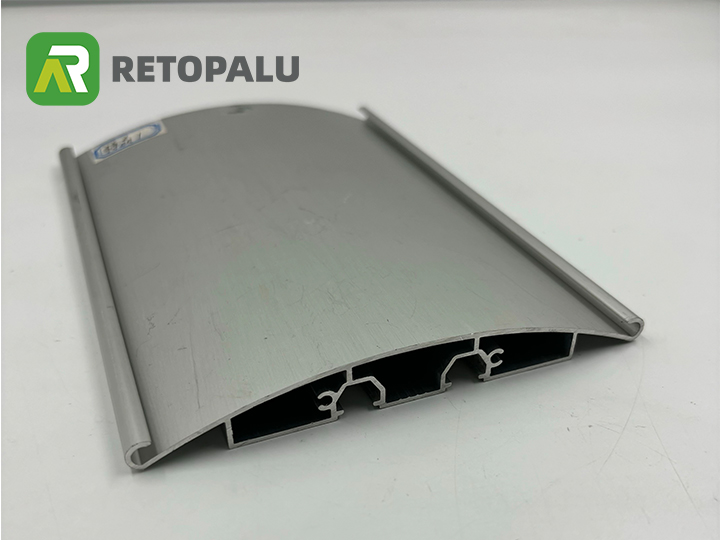

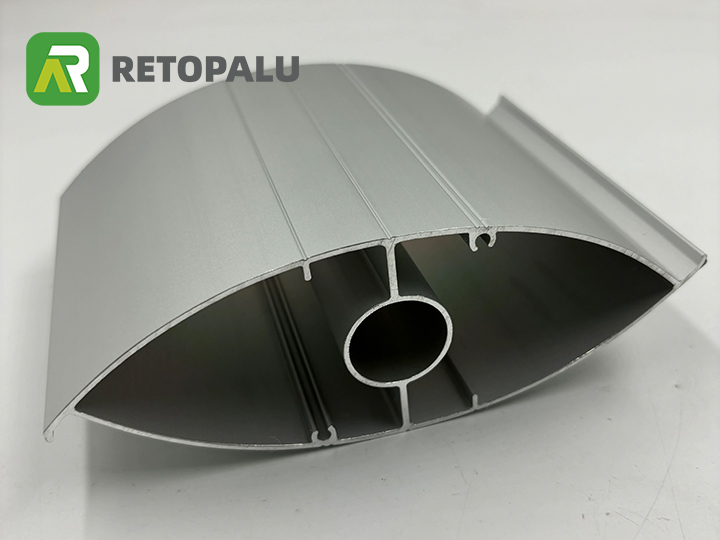

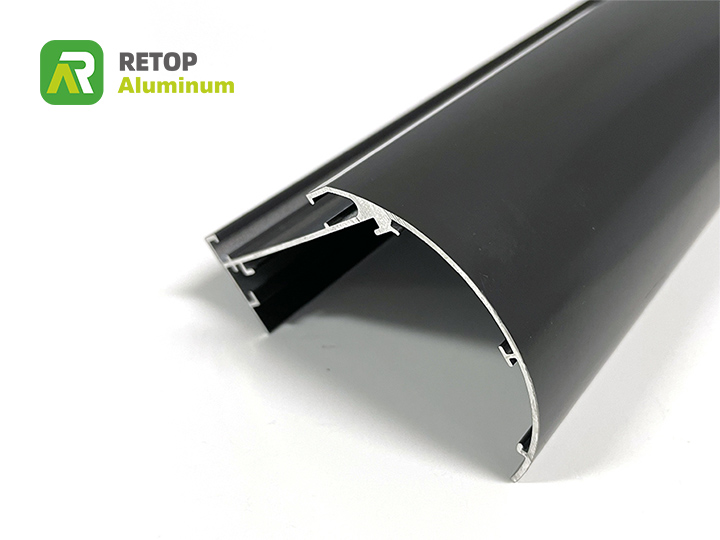

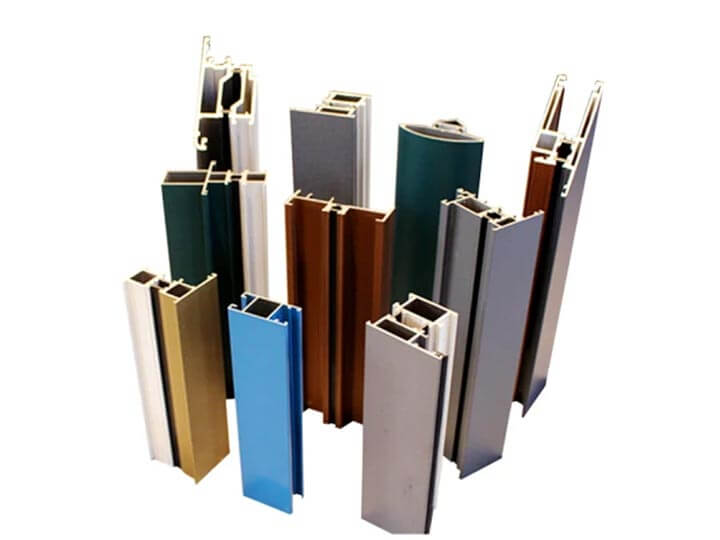

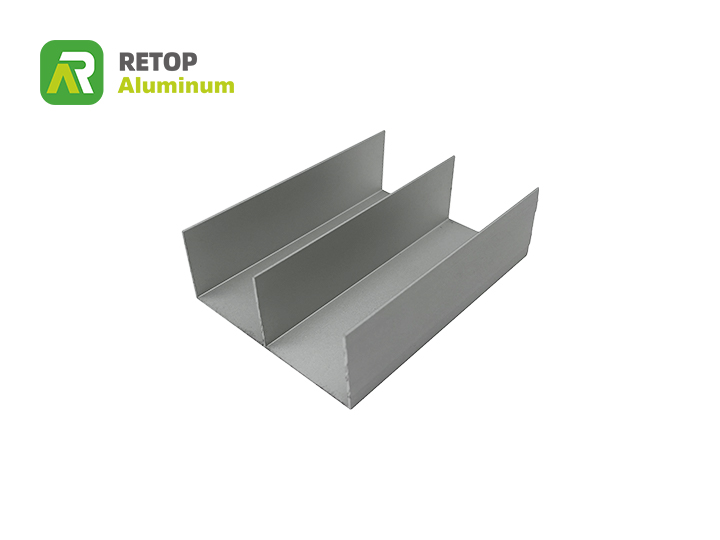

6063 aluminum profiles, on the other hand, have better surface finish and are more suitable for decorative applications such as window frames, door frames, and architectural trims. They are also more easily extruded, meaning they can be formed into more intricate shapes than 6061 profiles. However, they have lower strength and toughness than 6061 profiles, making them less suitable for heavy-duty applications.

T6 and 6063-T5 are specific temper designations of aluminum alloys 6061 and 6063, respectively. The temper designation refers to the processing or treatment that the alloy has undergone, which affects its mechanical properties such as strength, hardness, and ductility.6061-T6 aluminum profiles have undergone heat treatment to achieve the T6 temper designation, which involves solution heat treatment followed by artificial aging. This process results in improved strength and hardness, making 6061-T6 profiles suitable for high-stress applications such as aerospace, marine, and structural components. 6063-T5 aluminum profiles, on the other hand, have undergone heat treatment to achieve the T5 temper designation, which involves cooling the extruded profile rapidly after it has been formed and then artificially aging it. This process results in improved hardness and mechanical properties, making 6063-T5 profiles suitable for applications such as window and door frames, and decorative trims. In summary, the main difference between 6061-T6 and 6063-T5 aluminum profiles is their strength and suitability for different applications. 6061-T6 profiles are stronger and more suitable for heavy-duty applications, while 6063-T5 profiles are less strong but have better surface finish and are more suitable for decorative applications.